100% Original Factory Automatic Blister Packing Machine - LQ-BKL Series Semi-auto Granule Packing Machine – UPG

100% Original Factory Automatic Blister Packing Machine - LQ-BKL Series Semi-auto Granule Packing Machine – UPG Detail:

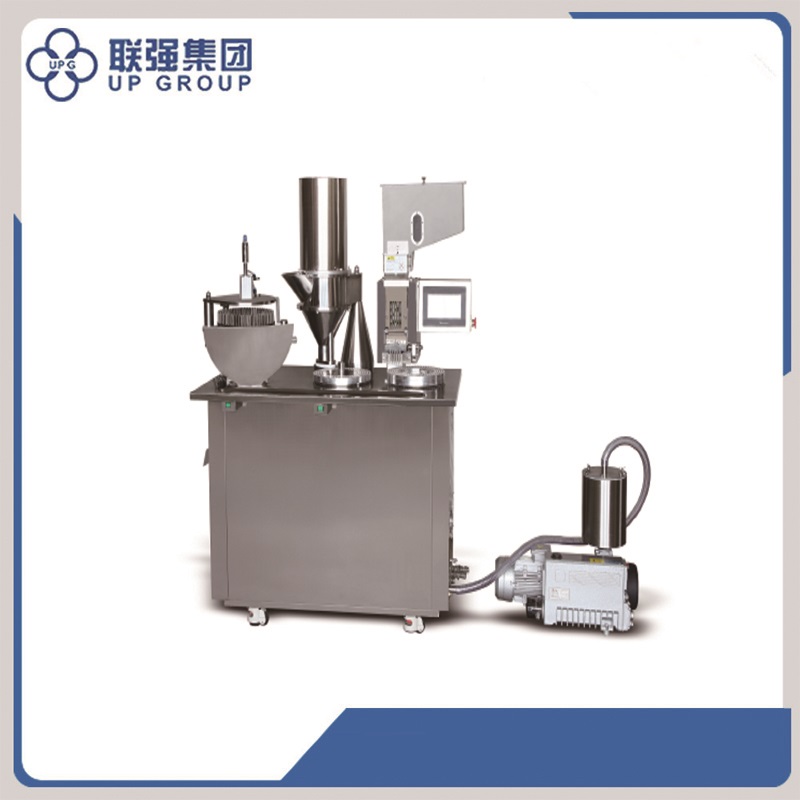

APPLY PHOTOS

INTRODUCTION AND OPERATION PROCESS

This machine is widely applicable to the automatic film packaging (with gold tear tape) of various single boxed articles. With new-type of double safeguard, no need to stop the machine, other spare parts will not be damaged when the machine runs out of step. Original unilateral hand swing device to prevent adverse shaking of the machine,And the non-rotation of the hand wheel when the machine keeps running to secure the security of the operator. No need to adjust the height of worktops on both sides of the machine when you need to replace moulds, no need to assemble or dismantle the material discharge chains and discharge hopper.

TECHNICAL PARAMETER

| Model | LQ-BTB-300A | LQ-BTB-350 |

| Packing Material | BOPP film and gold tear tape | BOPP film and gold tear tape |

| Packing Speed | 40-70 packs/Min | 30~60 packs/min |

| Max Packing Size | (L)240×(W)120×(H)60mm | (L)300×(W)120×(H)60mm |

| Electric Supply & Power | 220V 50Hz 5kw | 220V 50Hz 5kw |

| Weight | 500kg | 600kg |

| Overall Dimensions | 2000×700×1400mm(L*W*H) | (L)2000×(W)800×(H)1400mm |

FEATURE

1. No need to regulate the height of two work tops of the machine when the mould need to be replaced, no need to assemble or dismantle the material discharge chains and discharge hopper. Reduce the replacement time of the mould four hours to the present 30 minutes.

2. New-type double safeguard mechanisms are used, hence other spare parts will not be damaged when the machine runs out of step without stop of the machine.

3.Original unilateral hand swing device to prevent the machine shaking adversely, and the non-rotation of the hand wheel during the running of the machine can secure the security of the operator.

4. New-type double-rotary film cutter can ensure no need to mill the blade during many-year use of the machine, which overcomes the defect that the traditional stationary single-rotary film cutting cutter was easily worn.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping.Or irrevocable L/C at sight.

Warranty:

12 months after B/L date

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for 100% Original Factory Automatic Blister Packing Machine - LQ-BKL Series Semi-auto Granule Packing Machine – UPG , The product will supply to all over the world, such as: Bangalore, Rio de Janeiro, Moscow, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.