100% Original Factory Automatic Blister Packing Machine - LQ-SL Sleeve Labeling Machine – UPG

100% Original Factory Automatic Blister Packing Machine - LQ-SL Sleeve Labeling Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

This machine is used to put the sleeve label on the bottle and then shrink it. It is a popular packaging machine for bottles.

TECHNICAL PARAMETER

|

Sleeve |

Model |

LQ-SL-100M |

LQ-SL-200M |

|

Speed |

About 6000 bottles/hour |

About 12000 bottles/hour |

|

|

Machine size (L*W*H) |

2100mm * 850mm * 2000mm |

2100mm * 850mm * 2000mm |

|

|

Weight |

600kgs |

600kgs |

|

|

Powder supply |

220V, 50Hz, 1 Ph |

220V, 50Hz, 1 Ph |

|

|

Machine power |

1.5KW |

1.5KW |

|

|

Steam |

Length |

2m |

2m |

|

Conveyor speed |

0-35m/min |

0-35m/min |

|

|

Steam pressure |

Max. 0.6Mpa |

Max. 0.6Mpa |

|

|

Steam volume |

35-50kg/h |

35-50kg/h |

|

|

Machine size |

L2000*W400*H1500mm |

L2000*W400*H1500mm |

|

|

Weight |

230kg |

230kg |

|

|

Shrink Labels |

Materials |

PVC,PET,OPS |

PVC,PET,OPS |

|

Thickness |

0.035-0.13 mm |

0.035-0.13 mm |

|

|

Labels height |

30-250 mm |

30-250 mm |

|

|

Packed Bottles |

Height |

Customized as milk powder can. |

Customized as milk powder can. |

|

Material |

Glass,Metal,Plastic |

Glass,Metal,Plastic |

|

|

Shapes |

Round, square, flat , curved cup-shaped bottles |

Round, square, flat , curved cup-shaped bottles |

FEATURE

● Unique cutter head in China, the cutter head is completely out of replacement and adjustment.

● Single label feeding tray: moderate height favors label fixing; automatically controlled by micro-computer; free of setting and adjustment, only need to push the button and then label is in automatic detection & positioning; swift and labor-saving for changing labels, absolutely precise cutting-off position.

● Label feeding part: dynamic-force synchronous tension controls label feeding, feeding capability: 90m/min. Stable tension of label feeding part ensures the precise of the length of label, stable and fast feeding and the precise of delivering label and casting label.

● New-type cutter: driven by stepping motors, high speed, stable and precise cutting, smooth cut, good-looking shrinking; matched with label synchronous positioning part, the precise of cut positioning reaches 1mm.

● Multi-point emergency halt button: emergency buttons can be set in proper position of production lines so as to make safe and production smooth.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

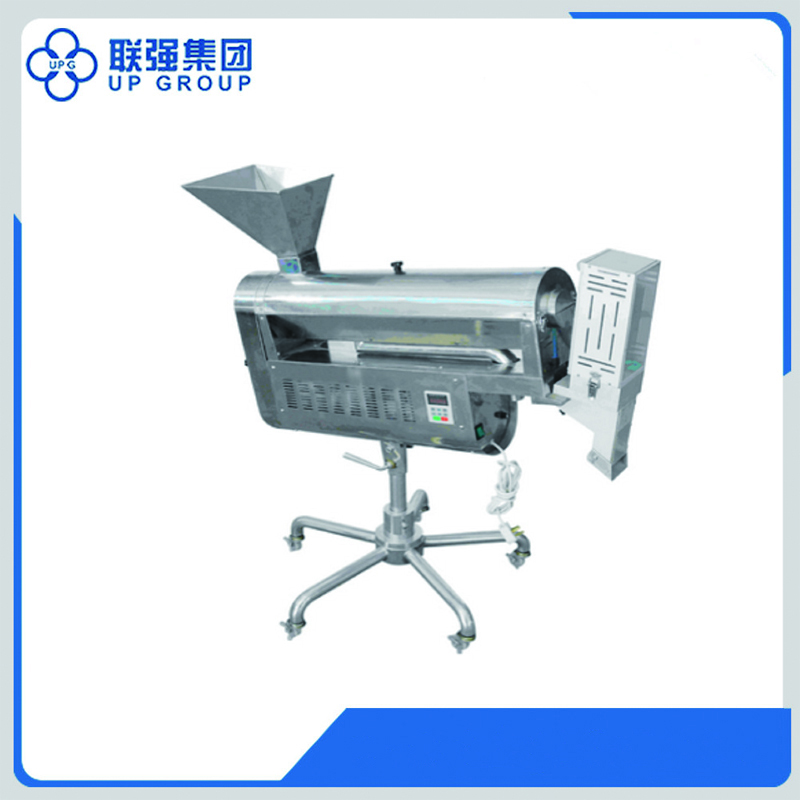

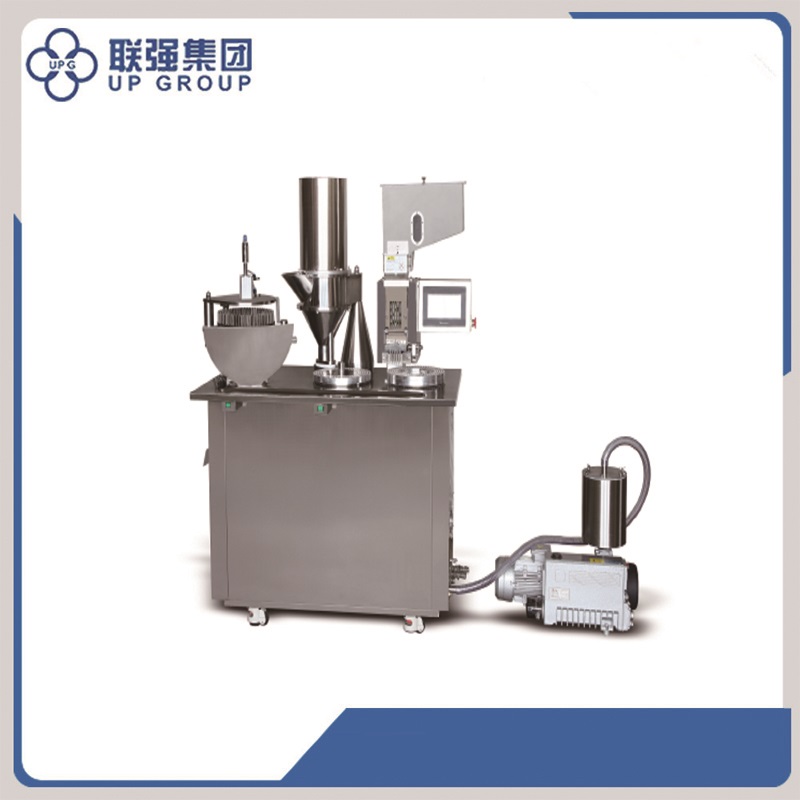

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for 100% Original Factory Automatic Blister Packing Machine - LQ-SL Sleeve Labeling Machine – UPG , The product will supply to all over the world, such as: Sao Paulo, Angola, Istanbul, We've got a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will absolutely benefit in both short and long run.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!