100% Original Shrink Wrap Machine Heat Sealer - LQ-BY Coating Pan – UPG

100% Original Shrink Wrap Machine Heat Sealer - LQ-BY Coating Pan – UPG Detail:

APPLY PHOTOS

INTRODUCTION

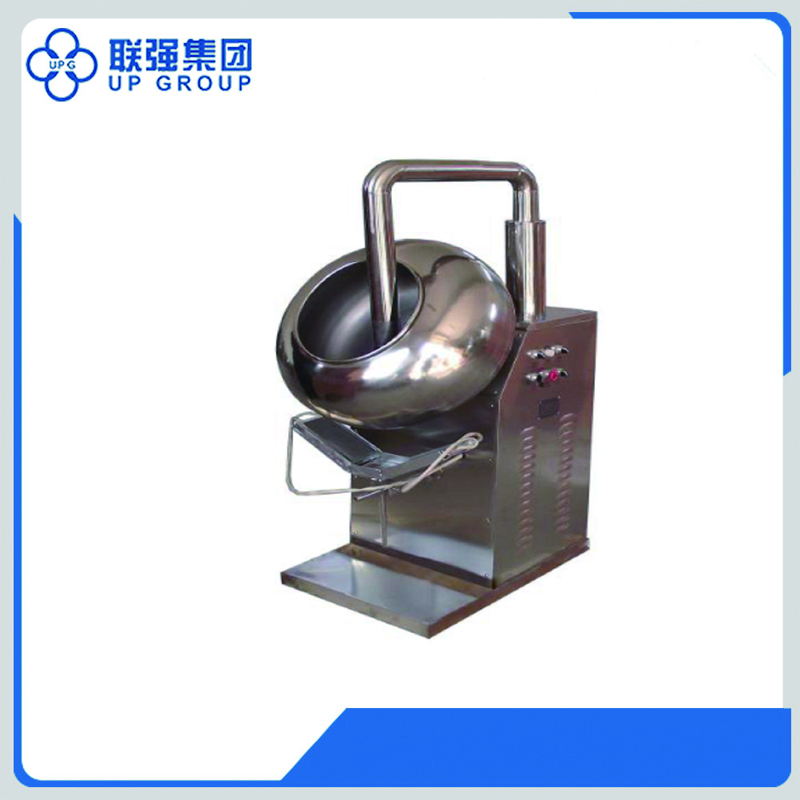

The tablet coating machine (sugar coating machine) is used to pills for pharmaceutical and sugar coating the tablets and food industries. It is also used for rolling and heating beans and edible nuts or seeds.

The tablet coating machine is widely used for making tablets, sugar-coat pills, polishing and rolling food demanded by the pharmacy industry, chemical industry, foods, research institutes and hospitals. It can also produce new medicine for research institutions. The sugar-coat tablets that are polished possess a bright appearance. The intact solidified coat is formed and the surface sugar’s crystallization can prevent the chip from oxidative deterioration volatilization and cover the improper flavor of the chip. In this way, tablets are easier to be identified and their solution inside human stomachs can be lessened.

STRUCTURE

1. Base

2. Body

3. Blower

4. Motor

5. Inclination device

6. Cover

7. Speed reducer

8. Electrical control panel

10. Wind pipe

11. External heating device

12.Tray

13. Pot

TECHNICAL PARAMETER

| Model | BY600 | BY800 | BY1000 | BY1250 |

| Dia. of Pot | 600mm | 800mm | 1000mm | 1250mm |

| Capacity | 5~15kg | 30~50kg | 50~70kg | 90~150kg |

| Speed | 32r/min | 32r/min | 32r/min | 30r/min |

| Motor Power | 0.75kw | 1.1kw | 1.5kw | 2.2kw |

| Blower Power | 0.12kw | 0.2kw | 0.2kw | 0.55kw |

| Total Power | 1.87kw | 3.3kw | 3.7kw | 4.75kw |

| Voltage | 380V/50Hz/3Ph | 380V/50Hz/3Ph | 380V/50Hz/3Ph | 380V/50Hz/3Ph |

| Overall Dimension (L*W*H) |

780×600×1360mm | 1100×800×1680mm | 1150×1000×1680mm | 1340×1250×1680mm |

| Weight | 115kg | 270kg | 280kg | 400kg |

FEATURE

The coating pan rotates clockwise. Compound syrup and mix slurry is jetted into the pot by several times and they are coated on the chips. The sugar coated tablets rotate in the pot. At the same time, tablet surface moisture is moved by the wind and we can get qualified sugar coated pills.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

Related Product Guide:

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for 100% Original Shrink Wrap Machine Heat Sealer - LQ-BY Coating Pan – UPG , The product will supply to all over the world, such as: Madras, South Korea, Mauritius, We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.