18 Years Factory Toothpaste Packaging Machine - LQ-LF Single Head Vertical Liquid Filling Machine – UPG

18 Years Factory Toothpaste Packaging Machine - LQ-LF Single Head Vertical Liquid Filling Machine – UPG Detail:

INTRODUCTION

Piston fillers are designed to dispense a wide variety of liquid and semi-liquid products. It serves as ideal filling machines for the cosmetic, pharmaceutical, food, pesticide and other industries. They are completely powered by air, which makes them especially suitable for an explosion-resistant or moist production environment. All the components that come in contact with product are made of 304 stainless steel, processed by CNC machines. And the surface roughness of which are ensured to be lower than 0.8. It is these high quality components that help our machines achieve market leadership when compared with other domestic machines of the same type.

TECHNICAL PARAMETER

|

Model |

LQ-LF 1-3 |

LQ-LF 1-6 |

LQ-LF 1-12 |

LQ-LF 1-25 |

LQ-LF 1-50 |

LQ-LF 1-100 |

|

Filling Speed |

0 – 50 bottles/min (Depend on the material and its volume) |

|||||

|

Filing range |

15 ~ 30 ml |

15 ~ 60 ml |

3 ~ 120 ml |

60 ~ 250 ml |

120 ~ 500 ml |

250 ~ 1000 ml |

|

Filling Accuracy |

About ± 0.5% |

|||||

|

Air Pressure |

4 - 6 kg/cm2 |

|||||

FEATURE

1.This machine is controlled by compressed air, so they are suitable in explosion-resistant or moist environments.

2. Because of the pneumatic controls and mechanical positioning, it has a high filling accuracy.

3. The filling volume is adjusted using screws and the counter, which provides ease of adjustment and allows the operator to read the real-time filling volume on the counter.

4. When you need to stop the machine in an emergency, push the URGENT button. The piston will go back to its initial location and the filling will be stopped immediately.

5. Two filling modes for you to choose — ’Manual’ and ‘Auto’.

6.. Equipment malfunction is extremely rare.

7. Material barrel is optional.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

100% payment by T/T when confirming the order,or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

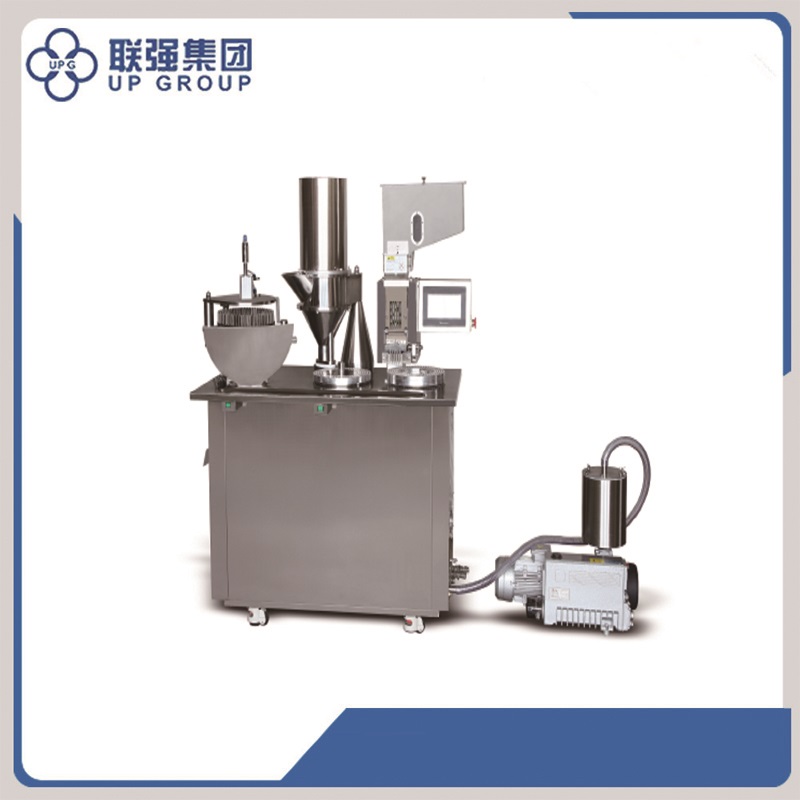

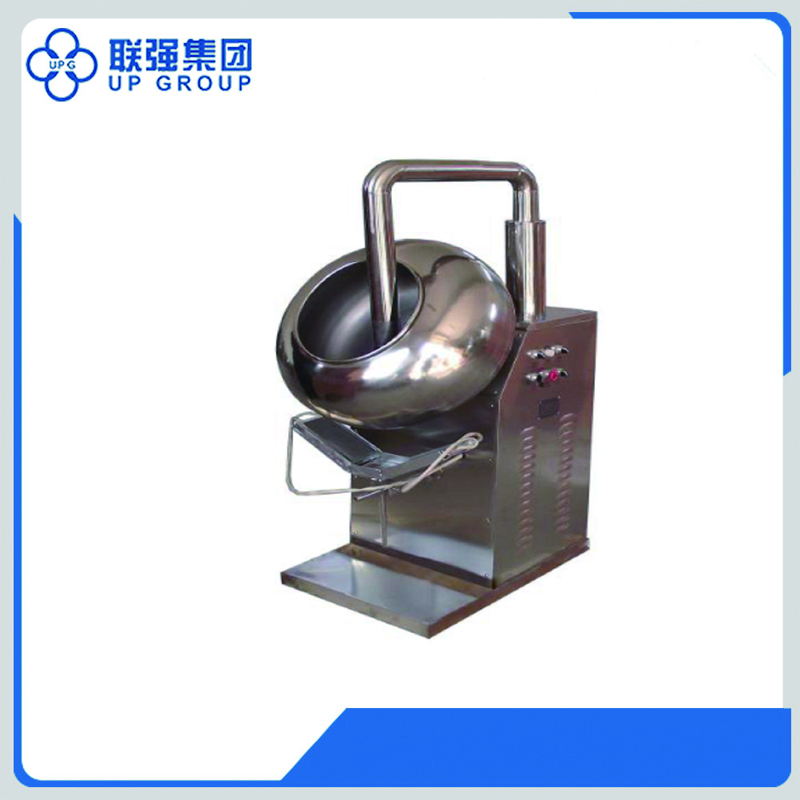

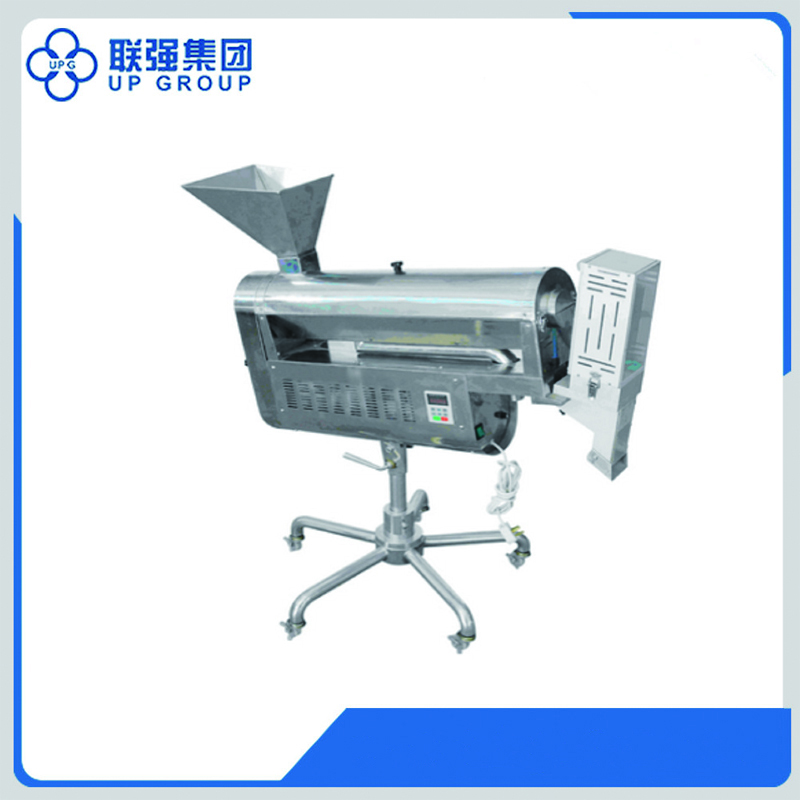

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for 18 Years Factory Toothpaste Packaging Machine - LQ-LF Single Head Vertical Liquid Filling Machine – UPG , The product will supply to all over the world, such as: Chile, America, Naples, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we're trying our best to be your good partner.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.