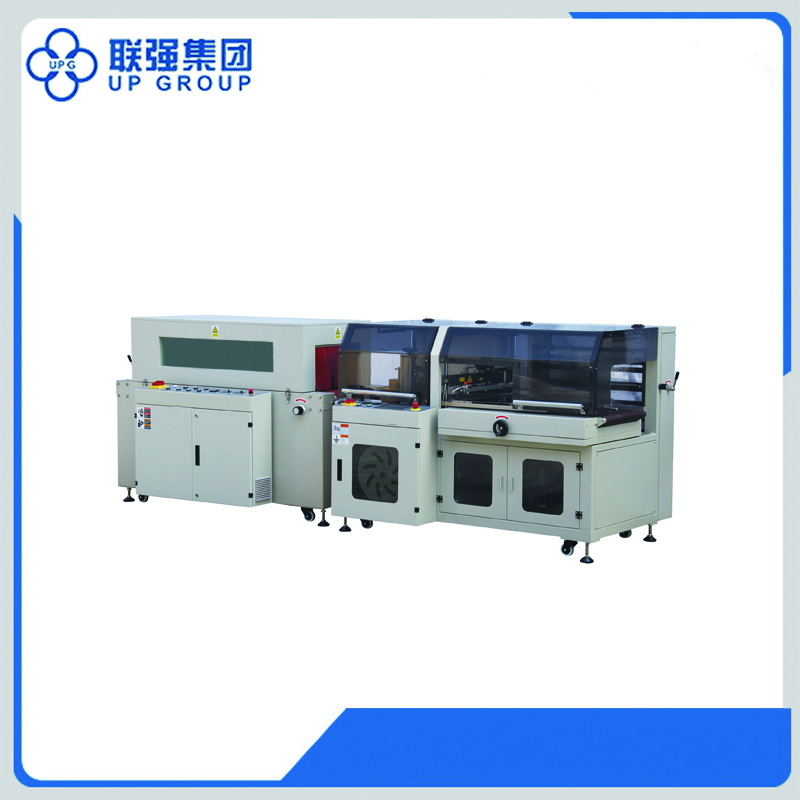

8 Year Exporter Heat Shrink Packing Machine - LQ-BTH-550+LQ-BM-500L Automatic High Speed Side Sealing Shrink Wrapping Machine – UPG

8 Year Exporter Heat Shrink Packing Machine - LQ-BTH-550+LQ-BM-500L Automatic High Speed Side Sealing Shrink Wrapping Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

This machine has an imported PLC automatic program control, easy operation, safety protection and alarm function that effectively prevents incorrect packaging. It is equipped with an imported horizontal and vertical detection photoelectric, which makes it easy to switch selections. The machine can be connected directly with the production line, no need additional operators.

TECHNICAL PARAMETER

| Model | LQ-BTH-550 | BM-500L |

| Max. Packing Size | L:No limited(W+H)≤550mmH≤250mm | L:No limited*(W)450mm*(H)250mm |

| Max. Sealing Size | L:No limited(W+H)≤550mm | (L)1500*(W)500*(H)300mm |

| Packing Speed | 1-30 Packages/min | 0-30m/min |

| Electric Suppy&Power | 220V/50Hz 3kw | 380V/50Hz 16kw |

| Air Pressure | 5.5kg/cm3 | / |

| Weight | 650kg | 470kg |

| Overall Dimensions | (L)2200*(W)1270*(H)1300mm | (L)1800*(W)1100*(H)1300mm |

FEATURE

1. Side blade sealing continuously makes the unlimited length of the product;

2. Side sealing lines can be adjusted to the desired position which based on the product’s height in order to achieve excellent sealing results;

3. It adopts the most advanced OMRON PLC controller and touch operator interface. Touch operator interface accomplish all working date easily;

4. Sealing knife uses the aluminum knife with DuPont Teflon with anti-stick coating & anti-high temperature to avoid cracking, coking and smoking with zero pollution. The sealing balance itself is also equipped with automatic protection function which effectively prevent from accidental cutting;

5. Automatic film feeding punching device is to drill away the air and make sure the packing result is good;

6. Equipped with imported USA Banner photoelectric of horizontal and vertical detection for choice to easily finish the sealing of thin and small items;

7. Manually adjustable film-guide system and feeding conveyor platform make the machine suitable for different width and height items. When the packaging size changes, the adjustment is very simple by rotating the hand wheel without changing molds and bag makers;

8. LQ-BM-500L adopts advance circulation blowing from the bottom of the tunnel, equipped double frequency inverter controls blowing, adjustable blowing direction and volume form bottom.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment: 30% deposit by T/T when confirming the order, 70% balance by T/T before shipping. Or irrevocable L/C at sight.

Delivery Time: 14 days after receiving deposit.

Warranty: 12 months after B/L date.

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of 8 Year Exporter Heat Shrink Packing Machine - LQ-BTH-550+LQ-BM-500L Automatic High Speed Side Sealing Shrink Wrapping Machine – UPG , The product will supply to all over the world, such as: Slovenia, Bangkok, Latvia, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!