Bottom price Cellophane Overwrapping Machine - LQ-NJP Automatic Hard Capsule Filling Machine – UPG

Bottom price Cellophane Overwrapping Machine - LQ-NJP Automatic Hard Capsule Filling Machine – UPG Detail:

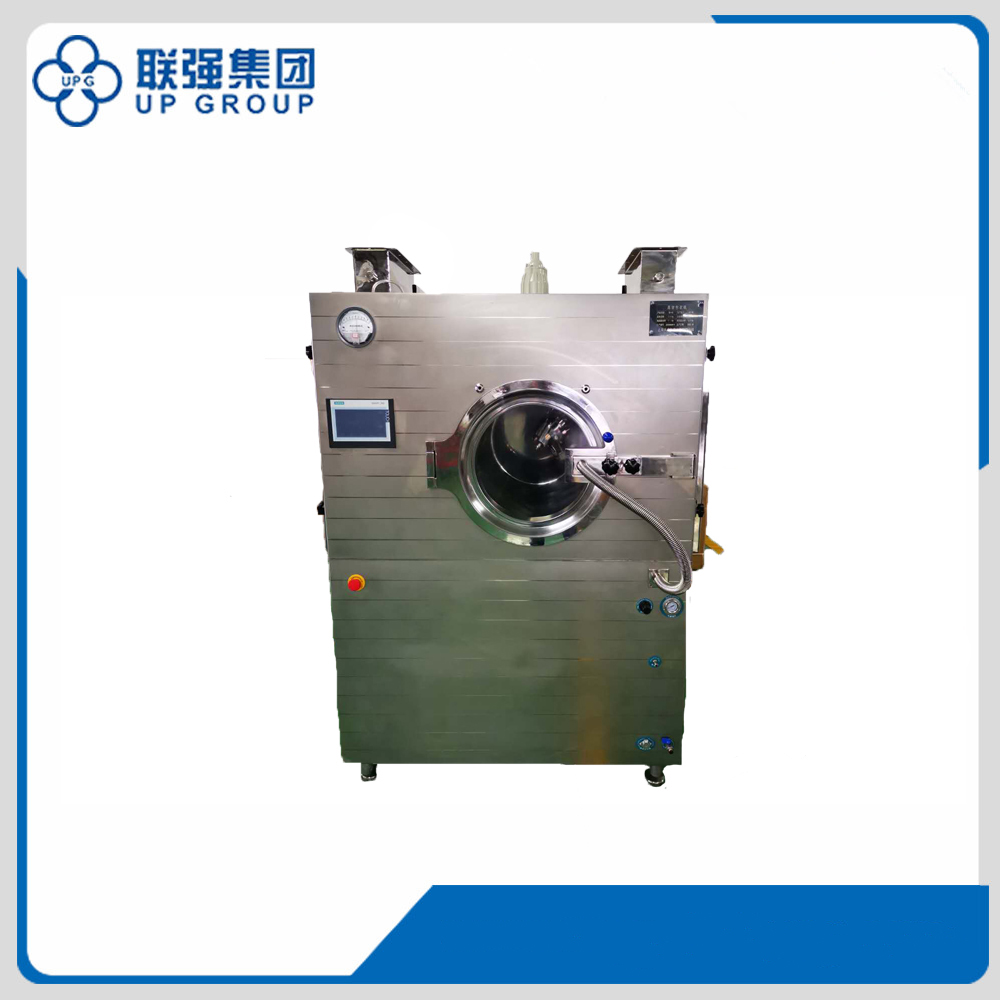

APPLY PHOTOS

INTRODUCTION

LQ-NJP series fully automatic capsule filling machine is designed and further improved on the base of original full automatic capsule filling machined,with high technology and exclusive performance. Its function can reach leading level in China. It is an ideal equipment for capsule and medicine in pharmaceutical industry.

TECHNICAL PARAMETER

|

Model |

LQ-NJP-400 |

LQ-NJP-800 |

LQ-NJP-1200 |

LQ-NJP-2300 |

|

Capacity |

400pcs/min |

800pcs/min |

1200pcs/min |

2300pcs/min |

|

Quantity Of Die Holes |

3 |

6 |

9 |

18 |

|

Capsule Size |

NO.00-5 |

|||

|

Fining Precision |

>99% |

|||

|

Voltage |

380V/50Hz/3Ph |

|||

|

Power |

3.5kw |

5kw |

5.5kw |

8kw |

|

Noise |

<80dBA |

|||

|

Vacuum Degree |

0.02-0.06Mpa |

|||

|

Overall Dimension(L*W*H) |

700*800* 1700mm |

860*960*1800mm |

960*1000*1900mm |

1180*1300* 1900mm |

|

Weight |

700kg |

900kg |

1100kg |

1500kg |

TECHNICAL PARAMETER

1. Good-looking appearance, exquisite workmanship, ease of operation, simplicity of use.

2. Stowage seat and measuring plate is designed as one unit to make measuring plate and stowage rod without deviation phenomenon, avoid friction phenomenon between stowage rod and measuring plate, improve its precision highly, furthermore, it prolongs the machine’s life greatly.

3. Ineligible capsule can be eliminated automatically. The medicine in the capsule can be recycled and be reused, thus it can increase greatly economic efficiency.

4. Simplicity and convenience of dismantling, installation and clean, various models of mould can be replaced each other, the mould of 800 model and 1000 model as well as 1200 model can be replaced mutually on the same machine to meet different requirement of capacity.

5. Dust collector and vacuum pipe as well as waste air pipe are installed in the inner of the machine to avoid the air pipe becoming hard, broken and leakage etc phenomenon, it is more convenient to clean the platform. Furthermore, it accords with the requirement of GMP that medicine can not contact with organic material.

6. The cap of stowage rod is made of stainless steel which replaces original plastic cap to void breaking phenomenon; the screws and caps on the platform is less than before.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

Related Product Guide:

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Bottom price Cellophane Overwrapping Machine - LQ-NJP Automatic Hard Capsule Filling Machine – UPG , The product will supply to all over the world, such as: Indonesia, Bangkok, Singapore, If any product meed your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality products, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!