factory customized China Granule Packing Machine - LQ-LS Series Screw Conveyor – UPG

factory customized China Granule Packing Machine - LQ-LS Series Screw Conveyor – UPG Detail:

APPLY PHOTOS

INTRODUCTION AND WORKING PRINCIPLE

Introduction:

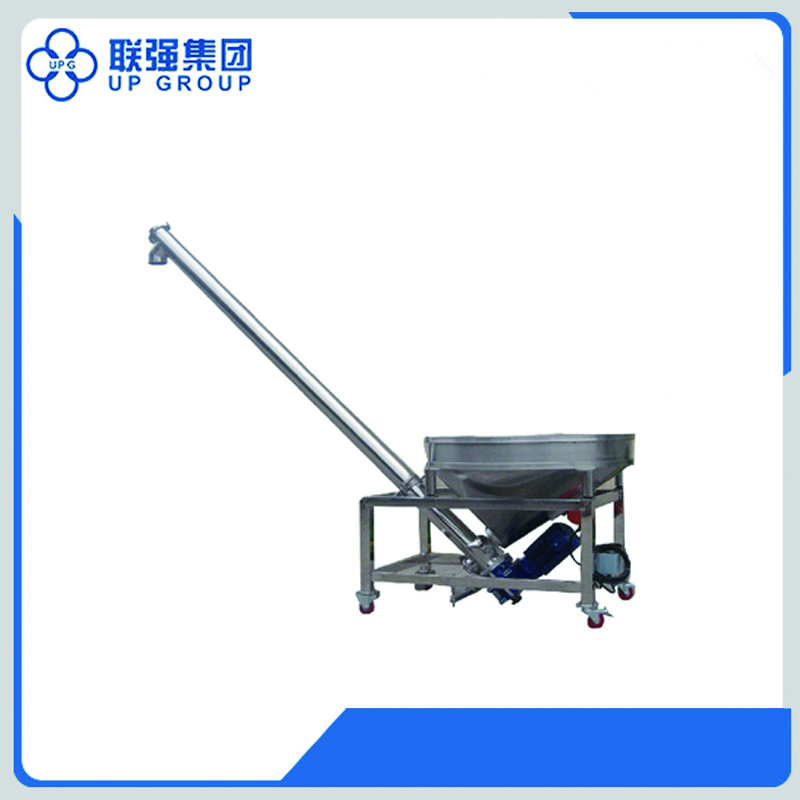

This conveyor is suitable for multiple powder. Working together with packaging machine, the conveyor of the product feeding is controlled to retain the product level in the product cabinet of packaging machine. And the machine can be used independently. All parts are made of stainless steel except the motor, bearing and support frame.

Working principle:

when the screw is rotating, under the multiple force of pushing of blade, gravity force of material, friction force between material and tube inwall, inner friction force of the material. The material move forward inside the tube with the form of relative slide between the screw blades and tube.

TECHNICAL PARAMETER

|

Model |

LQ-LS-R1 |

LQ- LS-R3 |

LQ- LS-S3 |

|

Feeding Capacity |

1m3/h |

3-5m3/h |

3m3/h |

|

Cabinet Volume |

110L |

230L |

230L |

|

Power Supply |

380V/220V/0HZ/3Phases |

380V/50HZ/3Phases |

|

|

Motor Power |

0.82 kw |

1.168 kw |

1.2 kw |

|

The Distance between the Outlet and Gruound |

1.6 m |

1.8 m |

|

|

Net Weight |

80 kg |

140 kg |

180 kg |

FEATURE

1. The cabinet vibrates by the steady rotation of the eccentric block which fixed on the principle axis of motor. This could avoid materials bridging of low flowability.

2. The amplitude could be adjustable and excitation efficient is high.

3. The machine adopts hoop fasten the end of screw which is convenient to disassemble and clean the whole screw.

4. The sensor and intelligent control circuit could be optional installed to control the material level, automatic feeding or overload warning.

5. Using double motors: feeding motor & vibrating motor, separately controlled. Product funnel is design to be vibrative adjustably, which lead to avoid product blocking and improve the adaptation of different products.

6. Product funnel can separate from the tube for easy assembly.

7. Special anti-dust design to protect bearing from dust.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

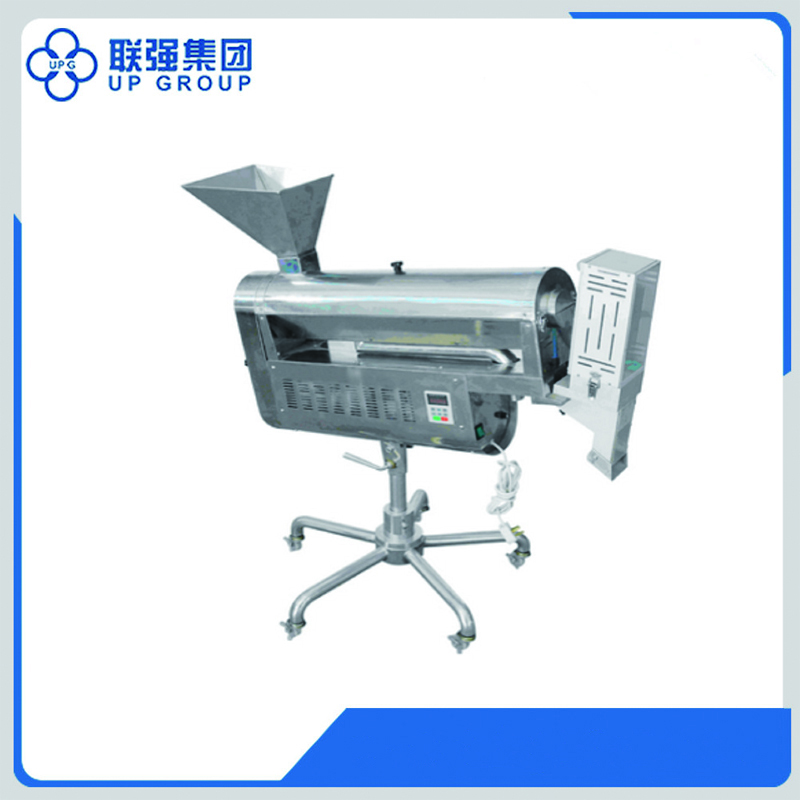

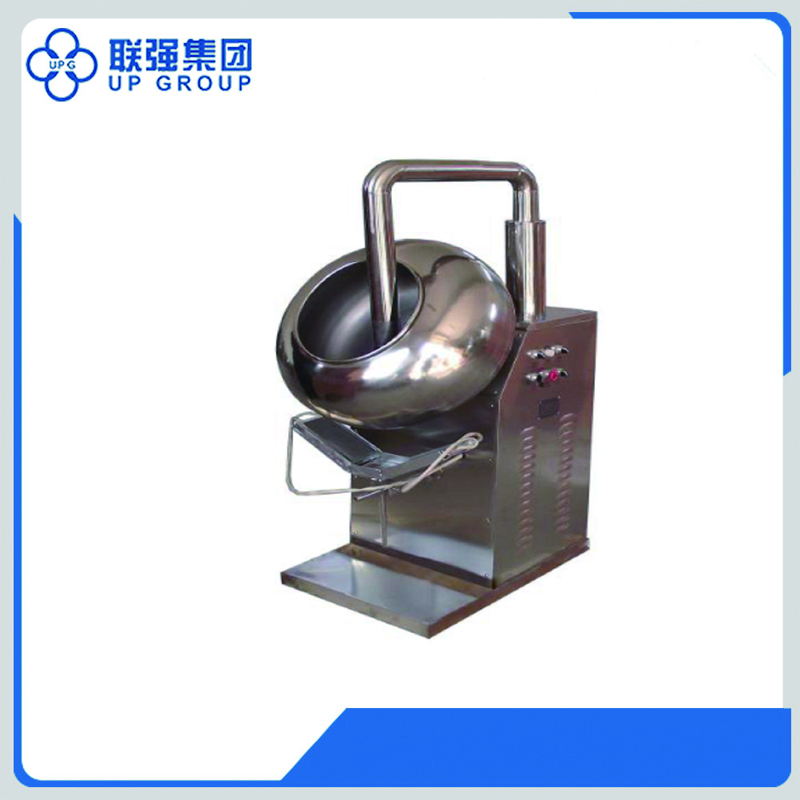

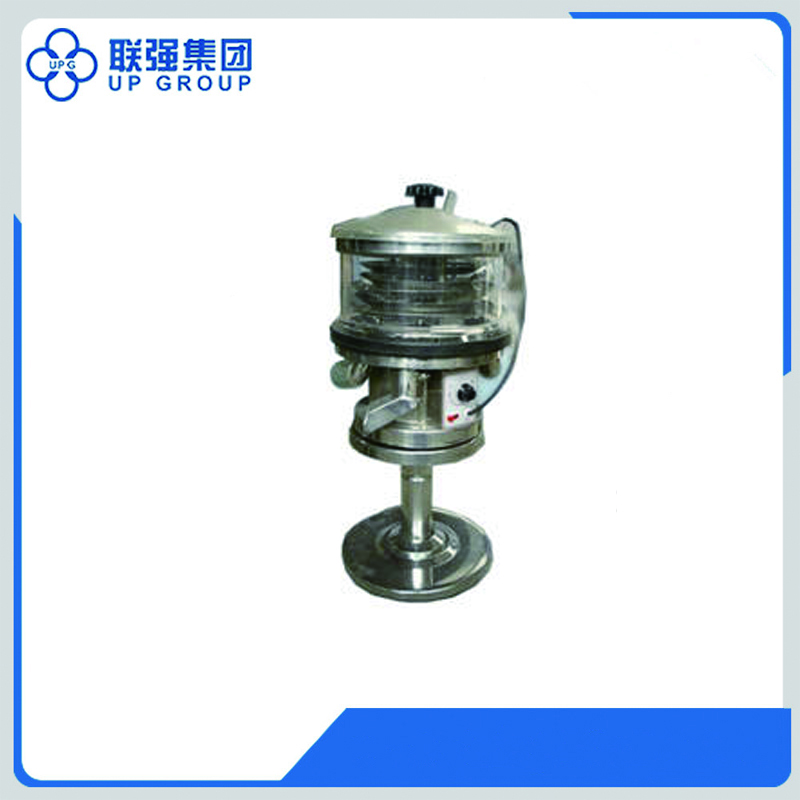

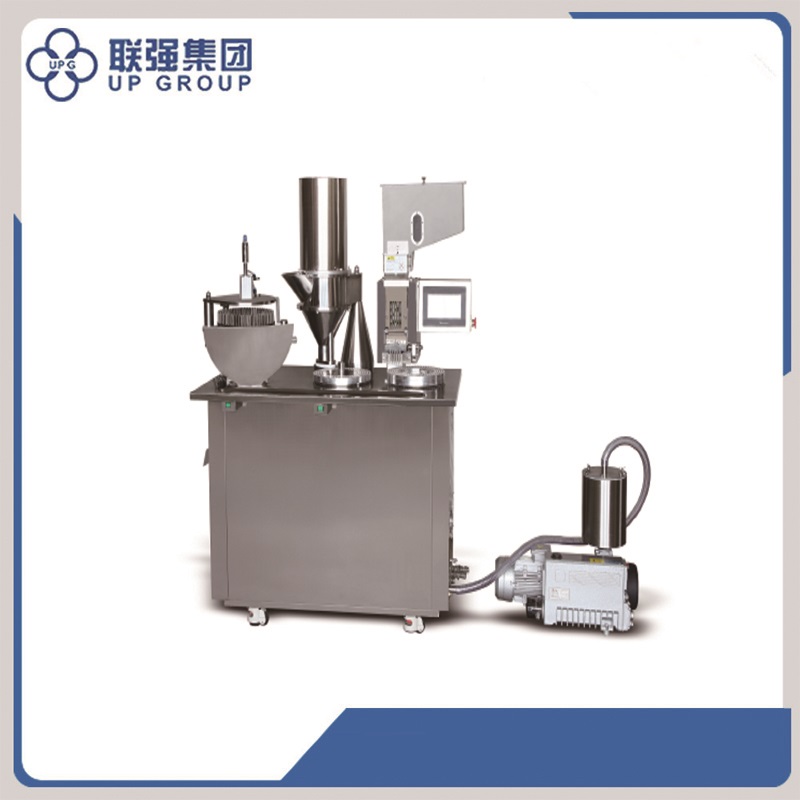

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for factory customized China Granule Packing Machine - LQ-LS Series Screw Conveyor – UPG , The product will supply to all over the world, such as: Lyon, Cape Town, kazakhstan, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We've got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!