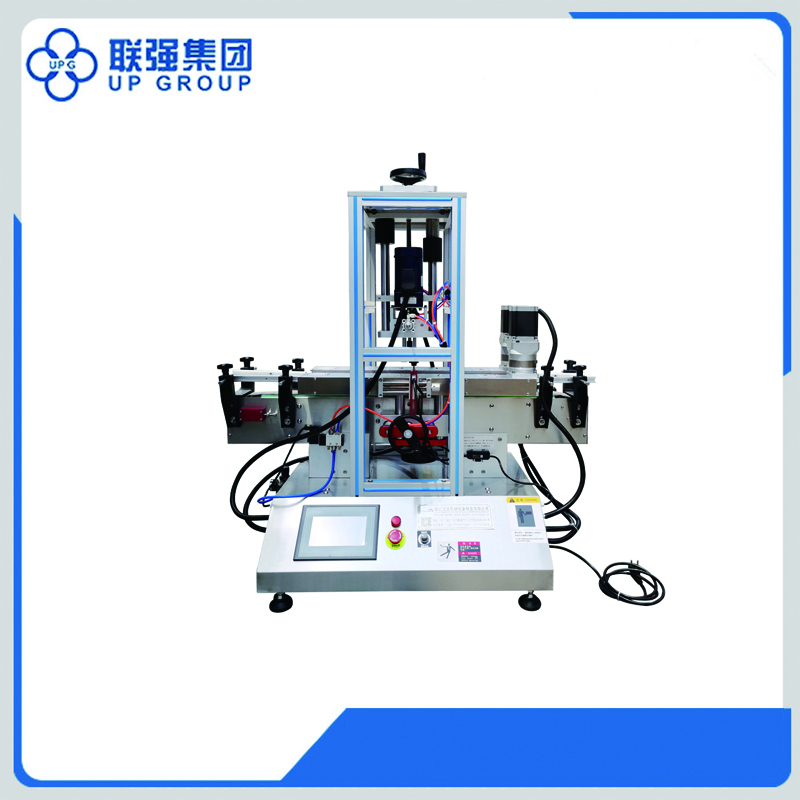

factory customized Heat Shrink Packaging Machine - LQ-DPB Automatic Blister Packing Machine – UPG

factory customized Heat Shrink Packaging Machine - LQ-DPB Automatic Blister Packing Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

Introduction:

The machine is specially designed for hospital dosage room, laboratory institute, health care product, middle-small pharmacy factory and featured by compact machine body, easy operation, multi-function, adjusting stroke. It is suitable for ALU-ALU and ALU-PVC package of medicine, food, electric parts etc.

TECHNICAL PARAMETER

|

Model |

LQ-DPB100 |

LQ-DPB140 |

LQ-DPB-250 |

|

Punch Frequency |

8-35 times/min |

8-35 times/min |

6-60 times/min |

|

Capacity |

2100 blisters/h |

4200 blisters/h |

9600-12000 blisters/h |

|

(Standard 80*57mm) |

(Standard 80*57mm) |

(Standard 80*57mm) |

|

|

Max Forming Area And Depth |

105*60*20 mm |

130*110*20 mm |

250*110*10 mm - 250*200*50 mm |

|

Stroke Range |

20-70 mm |

20-120 mm |

20-120 mm |

|

Standard Blister |

80*57、80*35、95*65、105*42、105*55 mm |

80*57 mm |

|

|

can be designed as user’s requirements) |

(can be designed as user’s requirements) |

||

|

Air Supply |

0.5Mpa-0.7Mpa 0.15m³/min |

0.6-0.8Mpa 0.15m³/min |

|

|

Total Power |

380V or 220V/50Hz/1.8kw | 380V or 220V/50Hz/3.2kw | 380V or 220V/50Hz/6kw |

|

Main Motor Power |

0.55kw |

0.75kw |

1.5kw |

|

PVC Hard Pieces |

(0.15-0.5)*115mm |

(0.15-0.5)*140mm |

(0.15-0.5)*260mm |

|

PTP Aluminum Foil |

(0.02-0.035)*115mm |

(0.02-0.035)*140mm |

(0.02-0.35)*260mm |

|

Dialytic Paper |

(50-100)g/m2*115mm |

(50-100)g/m2*140mm |

(50-100)g/m2*260mm |

|

Mould Cooling |

Tap water or recycled water |

||

|

Overall Dimension (L*W*H) |

1600*500*1200mm |

2300*560*1410mm |

3000*720*1600mm |

|

Weight |

600kg |

1000kg |

1700kg |

|

Model |

LQ-DPB100 |

LQ-DPB140 |

LQ-DPB-250 |

|

Punch Frequency |

8-35 times/min |

8-35 times/min |

6-60 times/min |

|

Capacity |

2100 blisters/h |

4200 blisters/h |

9600-12000 blisters/h |

|

(Standard 80*57mm) |

(Standard 80*57mm) |

( Standard 80*57mm) |

|

|

Max Forming Area And Depth |

105*60*20mm |

130*110*20mm |

250*110*10mm-250*200*50mm |

|

Stroke Range |

20-70mm |

20-120mm |

20-120mm |

|

Standard Blister |

80*57、80*35、95*65、105*42、105*55mm |

80*57m |

|

|

can be designed as user’s requirements) |

(can be designed as user’s requirements) |

||

|

Air Supply |

0.5Mpa-0.7Mpa, 0.15m3/min |

0.6-0.8Mpa, 0.3m3/min |

|

|

Total Power |

380V or 220V, 50Hz, 1.8kw | 380V or 220V, 50Hz, 3.2kw | 380V or 220V, 50Hz, 6kw |

|

Main Motor Power |

0.55kw |

0.75kw |

1.5kw |

|

PVC Hard Pieces |

(0.15-0.5)*115mm |

(0.15-0.5)*140mm |

(0.15-0.5)*260mm |

|

PTP Aluminum Foil |

(0.02-0.035)*115mm |

(0.02-0.035)*140mm |

(0.02-0.35)*260mm |

|

Dialytic Paper |

(50-100)g/m2*115mm |

(50-100)g/m2*140mm |

(50-100)g/m2*260mm |

|

Mould Cooling |

Tap water or recycled water |

||

|

Overall Dimension |

1600*500*1200mm |

2300*560*1410mm |

3000*720*1600mm |

|

Weight |

600kg |

1000kg |

1700kg |

FEATURE

1. Special machine-tool track type of casting machine-base, taken the process of backfire, maturing, to make the machine base without distortion.

2. Each box of section processed by professional equipment, to assure high precision and good interchangeability.

3. Forming, sealing, slitting parts are all could be adjusted freely on the track with triangle string and flat string.

4. Reducer adapts parallel-axes bevel gear wheel, to avoid loose and smooth between chain or strap when it is string.

5. Mold located by male pin, so that it is easy for changing. It is a multi-purpose machine which can pack any sizes and shapes of strip by changing the mold on the same machine, and it also can pack for liquid if liquid filling device equipped.

6. It adapts up and down reticulate pattern to conjugate, multi-step air cylinder, double-heat sealing makes good effect on sealing.

TERMS OF PAYMENT AND WARRANTY

Termsof Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping.Or irrevocable L/C at sight.

Warranty:

12 months after B/L date

Product detail pictures:

Related Product Guide:

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for factory customized Heat Shrink Packaging Machine - LQ-DPB Automatic Blister Packing Machine – UPG , The product will supply to all over the world, such as: Chile, America, Oman, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.