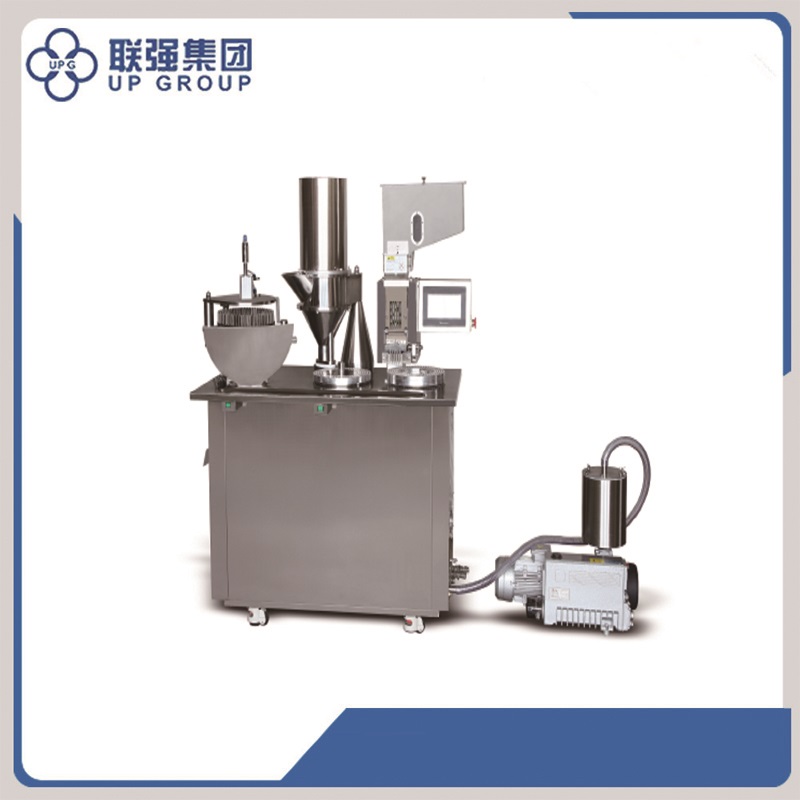

Free sample for Shrink Packing Machine - LQ-GF Automatic Tube Filling and Sealing Machine – UPG

Free sample for Shrink Packing Machine - LQ-GF Automatic Tube Filling and Sealing Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION AND WORKING PRINCIPLE

Introduction:

LQ-GF Series automatic tube filling and sealing machine applies for production in cosmetic, daily use industrial goods, pharmaceutical etc. It can fill the cream, ointment and sticky fluidextract into tube and then seal the tube and stamp number and discharge finished product.

Working Principle:

Automatic Tube Filling And Sealing Machine is designed for plastic tube and multiple tube filling and sealing in cosmetic, pharmacy, foodstuff, adhesives etc. industries.

The operating principle is to put the tubes which are in the feeding hopper into the first position of filling model individually and invert with rotating disk. It is used to test nomenclature plate in pipe when turning to the second position. Filling with nitrogen gas into pipe (optional) in the third position and filling with desired substance in the fourth, then heating, sealing, number printing, cooling, slivers trimming etc. Finally, export the finished products when inverting to the final position and it has twelve positions. Every tube should be taken such series processes to complete filling and sealing.

TECHNICAL PARAMETER

| Model | LQ-GF-400L | LQ-GF-400F | LQ-GF-800L | LQ-GF-800F |

| Tube Material | Metal Tube, ALU Tube | Plastic Tube, Laminate Tube | Metal Tube, ALU Tube | Plastic Tube, Laminate Tube |

| Dia. of Tube | 10-42mm | 10-60mm | 13-50mm | 13-60mm |

| Tube Length | 50-250mm (customized) | 50-240mm (customized) | 80-250mm (customized) | 80-260mm (customized) |

| Filling Volume | 5-500ml (Adjustable) | 5-800ml (Adjustable) | 5-400ml (Adjustable) | 5-600ml (Adjustable) |

| Filling Accuracy | ±1% | |||

| Capacity | 2160-6000pcs/h | 1800-5040pcs/h | 3600-7200pcs/h | 3600-7200pcs/h |

| Air Supply | (0.55-0.65) Mpa 0.1 m³/min | |||

| Voltage | 2kw(380V/220V 50HZ) | 2.2kw(380V/220V 50HZ) | ||

| Heat Sealing Power | 3kw | 6kw | ||

| Overall Dimension(L*W*H) | 2620x1020x1980mm | 2620x1020x1980mm | 3270x1470x2000mm | 3270x1470x2000mm |

| Weight | 1100kg | 1100kg | 2200kg | 2200kg |

FEATURE

1. Accuracy filling, balanced action, low buzz.

2. Automatically finished overall process as tube supply, photo-electron register, inert gases filling (optional), material filling and sealing, batch number printing, and finished products output.

3. Quickly and accurately adjust and it is suitable for varies specification and varies product producing.

4. No tube no filling function and warning if tube error positioned or pressure too low, automatic stop machine if opening the protective door.

TERMS OF PAYMENT AND WARRANTY

Terms Of Payment:

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.

Warranty:

12 months after B/L date

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for Free sample for Shrink Packing Machine - LQ-GF Automatic Tube Filling and Sealing Machine – UPG , The product will supply to all over the world, such as: Guatemala, Spain, Madrid, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.