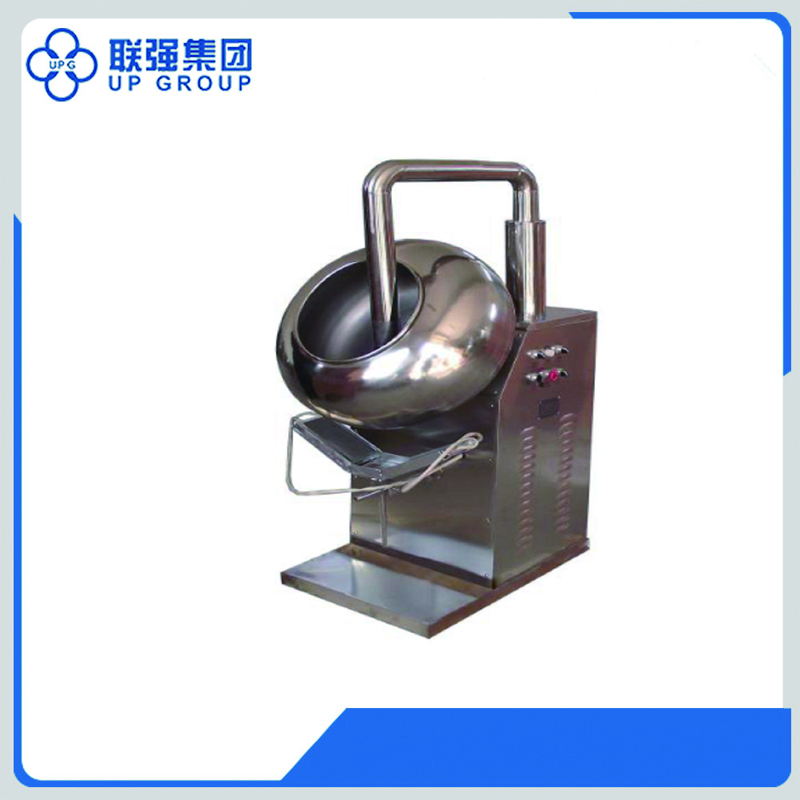

Hot New Products Screw Conveyor System - LQ-BY Coating Pan – UPG

Hot New Products Screw Conveyor System - LQ-BY Coating Pan – UPG Detail:

APPLY PHOTOS

INTRODUCTION

The tablet coating machine (sugar coating machine) is used to pills for pharmaceutical and sugar coating the tablets and food industries. It is also used for rolling and heating beans and edible nuts or seeds.

The tablet coating machine is widely used for making tablets, sugar-coat pills, polishing and rolling food demanded by the pharmacy industry, chemical industry, foods, research institutes and hospitals. It can also produce new medicine for research institutions. The sugar-coat tablets that are polished possess a bright appearance. The intact solidified coat is formed and the surface sugar’s crystallization can prevent the chip from oxidative deterioration volatilization and cover the improper flavor of the chip. In this way, tablets are easier to be identified and their solution inside human stomachs can be lessened.

STRUCTURE

1. Base

2. Body

3. Blower

4. Motor

5. Inclination device

6. Cover

7. Speed reducer

8. Electrical control panel

10. Wind pipe

11. External heating device

12.Tray

13. Pot

TECHNICAL PARAMETER

| Model | BY600 | BY800 | BY1000 | BY1250 |

| Dia. of Pot | 600mm | 800mm | 1000mm | 1250mm |

| Capacity | 5~15kg | 30~50kg | 50~70kg | 90~150kg |

| Speed | 32r/min | 32r/min | 32r/min | 30r/min |

| Motor Power | 0.75kw | 1.1kw | 1.5kw | 2.2kw |

| Blower Power | 0.12kw | 0.2kw | 0.2kw | 0.55kw |

| Total Power | 1.87kw | 3.3kw | 3.7kw | 4.75kw |

| Voltage | 380V/50Hz/3Ph | 380V/50Hz/3Ph | 380V/50Hz/3Ph | 380V/50Hz/3Ph |

| Overall Dimension (L*W*H) |

780×600×1360mm | 1100×800×1680mm | 1150×1000×1680mm | 1340×1250×1680mm |

| Weight | 115kg | 270kg | 280kg | 400kg |

FEATURE

The coating pan rotates clockwise. Compound syrup and mix slurry is jetted into the pot by several times and they are coated on the chips. The sugar coated tablets rotate in the pot. At the same time, tablet surface moisture is moved by the wind and we can get qualified sugar coated pills.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

Related Product Guide:

Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of Hot New Products Screw Conveyor System - LQ-BY Coating Pan – UPG , The product will supply to all over the world, such as: Austria, Pretoria, Czech Republic, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.