Newly Arrival Cookies Packing Machine - LQ-ZHJ Automatic Cartoning Machine – UPG

Newly Arrival Cookies Packing Machine - LQ-ZHJ Automatic Cartoning Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

This machine is suitable for packing blisters, tubes, ampules and other related objects into boxes. This machine can fold leaflet, open box, insert blister into box, emboss batch number and close box automatically. It adopts frequency inverter to adjust speed, human machine interface to operate, PLC to control and photoelectric to supervise and control each station the reasons automatically, which can solve the troubles in time. This machine can be used separately and also can be linked with other machines to be a production line. This machine can also be equipped with hot melt glue device to do hot melt glue sealing for box.

TECHNICAL PARAMETER

| Model | LQ-ZHJ-120 | LQ-ZHJ-200 | LQ-ZHJ-260 |

| Production capacity | 120 boxes/min | 200 boxes/min | 260 boxes/min |

| Max. Size of Box | 200*120*70 mm | 200*80*70 mm | 200*80*70 mm |

| Min. Size of Box | 50*25*12 mm | 65*25*15 mm | 65*25*15 mm |

| Specification of Box | 250-300 g/m2 | 250-300 g/m2 | 250-300 g/m2 |

| Max. Size of Leaflet | 260*180 mm | 560*180 mm | 560*180 mm |

| Max. Size of Leaflet | 110*100 mm | 110*100 mm | 110*100 mm |

| Specification of Leaflet | 55-65 g/m2 | 55-65 g/m2 | 55-65 g/m2 |

| Volume of Air Consumption | 20 m³/h | 20 m³/h | 20 m³/h |

| Total Power | 1.5 kw | 4.1 kw | 6.9 kw |

| Voltage | 380V/50Hz/3Ph | 380V/50Hz/3Ph | 380V/50Hz/3Ph |

| Overall Dimension (L*W*H) | 3300*1350*1700 mm | 4500*1500*1700 mm | 4500*1500*1700 mm |

| Weight | 1500 kg | 3000 kg | 3000 kg |

FEATURE

1. It has advantages of high packing efficiency and good quality.

2. This machine can fold leaflet, open box, insert blister into box, emboss batch number and close box automatically.

3. It adopts frequency inverter to adjust speed, human machine interface to operate, PLC to control and photoelectric to supervise and control each station the reasons automatically, which can solve the troubles in time.

4. This machine can be used separately, and also can be linked to other machine to be a production line.

5. It can also equip with hot melt glue device to do hot melt glue sealing for box. (Optional)

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

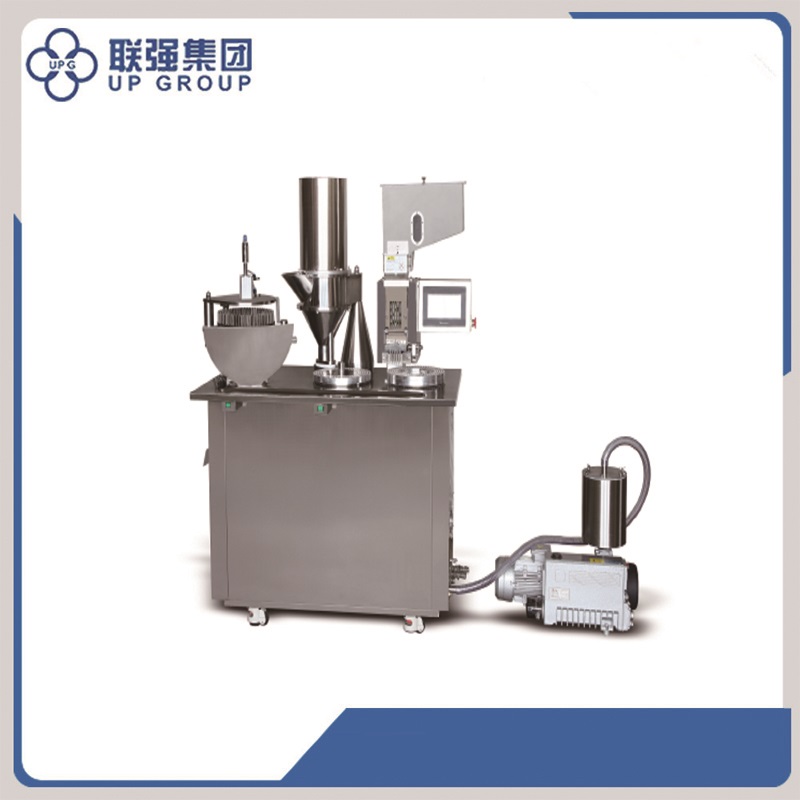

Product detail pictures:

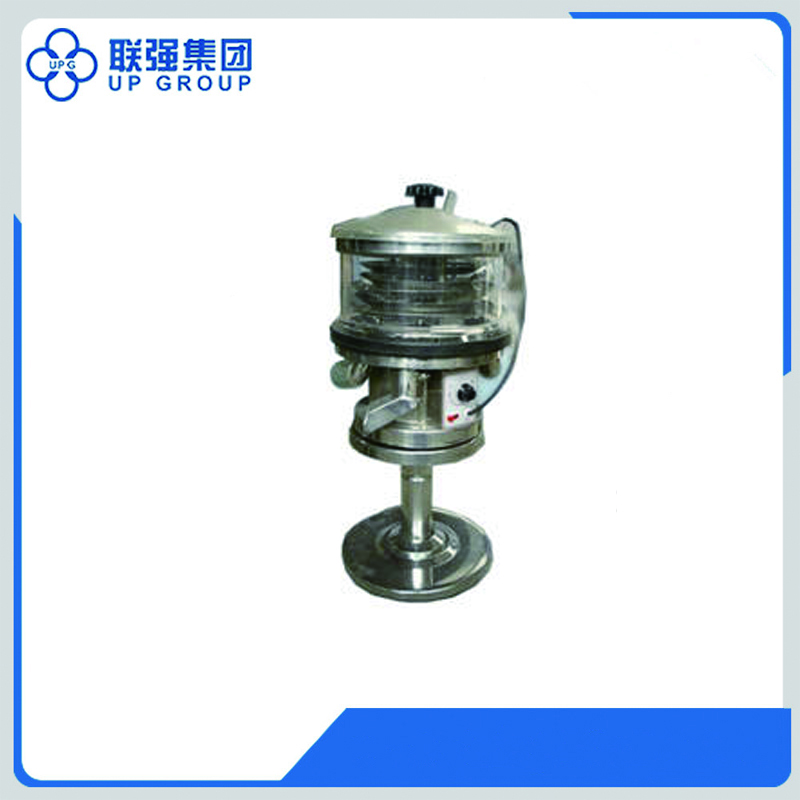

Related Product Guide:

We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Newly Arrival Cookies Packing Machine - LQ-ZHJ Automatic Cartoning Machine – UPG , The product will supply to all over the world, such as: Palestine, Malta, Cairo, We aspire to meet the demands of our customers globally. Our range of merchandise and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.