OEM Customized Drip Coffee Bag Machine - LQ-DTJ / LQ-DTJ-V Semi-auto Capsule Filling Machine – UPG

OEM Customized Drip Coffee Bag Machine - LQ-DTJ / LQ-DTJ-V Semi-auto Capsule Filling Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

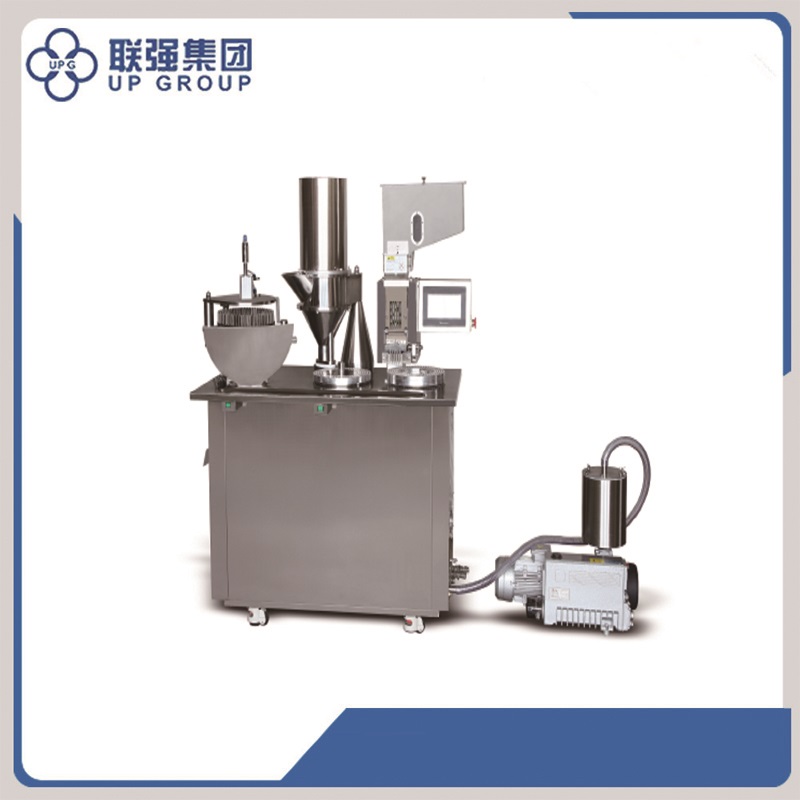

This type capsule filling machine is a new efficient equipment based on old type after research and development: easier more intuitive and higher loading in capsule dropping, U-turning, vacuum separation in comparison with the old type. The new type of capsule orientating adopts columns pill positioning design, which shortens the time in the replacement of mould from the original 30 minutes to 5-8 minutes. This machine is one type of electricity and pneumatic combined control, automatic counting electronics, programmable controller and frequency conversion speed regulating device. Instead of manual filling, it reduces labor intensity, which is the ideal equipment for capsule filling for small and medium-sized pharmaceutical companies, pharmaceutical research and development institutions and hospital preparation room.

The machine consists of capsule-feeding, U-turning and separating mechanism, material medicine-filling mechanism, locking device, electronic speed varying and adjusting mechanism, electrical and pneumatic control system protection device as well as accessories such as vacuum pump and air pump.

China machine-made capsules or the imported are applicable to this machine, with which the finished product qualification rate can be above 98%.

TECHNICAL PARAMETER

| Model | LQ-DTJ-C (Semi-Auto Locking) | LQ-DTJ-V (Automatic Locking) |

| Capacity | 15000-28000pcs/h (with single set mould) | 15000-28000pcs/h (with single set mould) |

| Applicable Capsules | 000#/00#/0#/1#/2#/3#/4#/5# | 000#/00#/0#/1#/2#/3#/4#/5# |

| machine-made standard capsules | machine-made standard capsules | |

| Filling Material | Powder or small granules(can not be wet and sticky) | Powder or small granules(can not be wet and sticky) |

| Air Pressure | 0.03m3/min,0.7Mpa | 0.03m3/min,0.7Mpa |

| Vacuum Pump | 40m3/h | 40m3/h |

| Total Power | 2.12kw,380V,50Hz,3Phs | 2.12kw,380V,50Hz,3Phs |

| Overall Dimension | 1300*800*1750mm (L*W*H) | 1300*800*1750mm (L*W*H) |

| Weight | 400kg | 400kg |

TERMS OF PAYMENT AND WARRANTY

Terms of Payment: 30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Delivery Time: 14 days after receiving deposit.

Warranty: 12 months after B/L date

Product detail pictures:

Related Product Guide:

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for OEM Customized Drip Coffee Bag Machine - LQ-DTJ / LQ-DTJ-V Semi-auto Capsule Filling Machine – UPG , The product will supply to all over the world, such as: Guinea, United Kingdom, Montreal, Our Company has qualified engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the items, Be sure to feel free to contact us.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!