OEM/ODM China Lipton Tea Packaging Machine - LQ-BKL Series Semi-auto Granule Packing Machine – UPG

OEM/ODM China Lipton Tea Packaging Machine - LQ-BKL Series Semi-auto Granule Packing Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION AND OPERATION PROCESS

This machine is widely applicable to the automatic film packaging (with gold tear tape) of various single boxed articles. With new-type of double safeguard, no need to stop the machine, other spare parts will not be damaged when the machine runs out of step. Original unilateral hand swing device to prevent adverse shaking of the machine,And the non-rotation of the hand wheel when the machine keeps running to secure the security of the operator. No need to adjust the height of worktops on both sides of the machine when you need to replace moulds, no need to assemble or dismantle the material discharge chains and discharge hopper.

TECHNICAL PARAMETER

| Model | LQ-BTB-300A | LQ-BTB-350 |

| Packing Material | BOPP film and gold tear tape | BOPP film and gold tear tape |

| Packing Speed | 40-70 packs/Min | 30~60 packs/min |

| Max Packing Size | (L)240×(W)120×(H)60mm | (L)300×(W)120×(H)60mm |

| Electric Supply & Power | 220V 50Hz 5kw | 220V 50Hz 5kw |

| Weight | 500kg | 600kg |

| Overall Dimensions | 2000×700×1400mm(L*W*H) | (L)2000×(W)800×(H)1400mm |

FEATURE

1. No need to regulate the height of two work tops of the machine when the mould need to be replaced, no need to assemble or dismantle the material discharge chains and discharge hopper. Reduce the replacement time of the mould four hours to the present 30 minutes.

2. New-type double safeguard mechanisms are used, hence other spare parts will not be damaged when the machine runs out of step without stop of the machine.

3.Original unilateral hand swing device to prevent the machine shaking adversely, and the non-rotation of the hand wheel during the running of the machine can secure the security of the operator.

4. New-type double-rotary film cutter can ensure no need to mill the blade during many-year use of the machine, which overcomes the defect that the traditional stationary single-rotary film cutting cutter was easily worn.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping.Or irrevocable L/C at sight.

Warranty:

12 months after B/L date

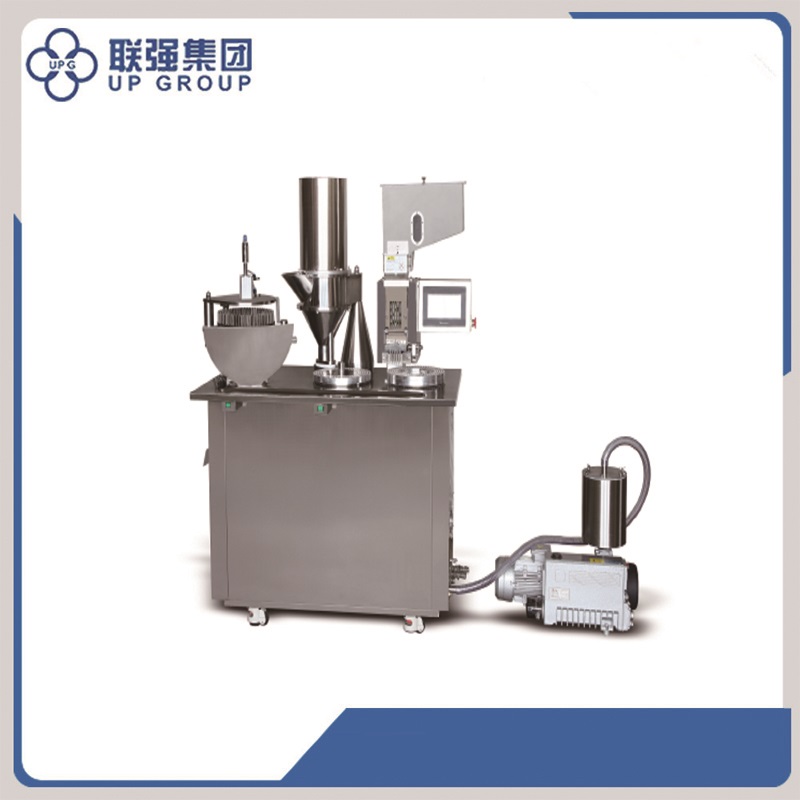

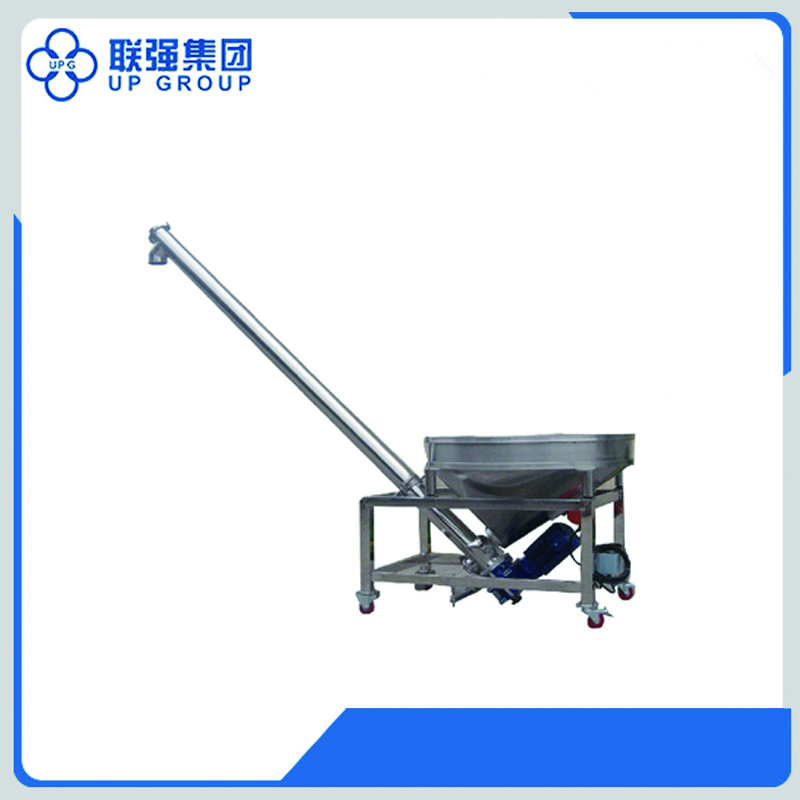

Product detail pictures:

Related Product Guide:

Our firm has been concentrating on brand strategy. Customers' satisfaction is our best advertising. We also offer OEM provider for OEM/ODM China Lipton Tea Packaging Machine - LQ-BKL Series Semi-auto Granule Packing Machine – UPG , The product will supply to all over the world, such as: Ecuador, United Arab Emirates, Kuwait, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.