-

LQ-TB-300 Cellophane Wrapping Machine

This machine is widely applicable to the automatic film packaging (with gold tear tape) of various single boxed articles. With new-type of double safeguard, no need to stop the machine, other spare parts will not be damaged when the machine runs out of step.. Original unilateral hand swing device to prevent adverse shaking of the machine, and the non-rotation of the hand wheel when the machine keeps running to secure the security of the operator. No need to adjust the height of worktops on both sides of the machine when you need to replace mould, no need to assemble or dismantle the material discharge chains and discharge hopper.

-

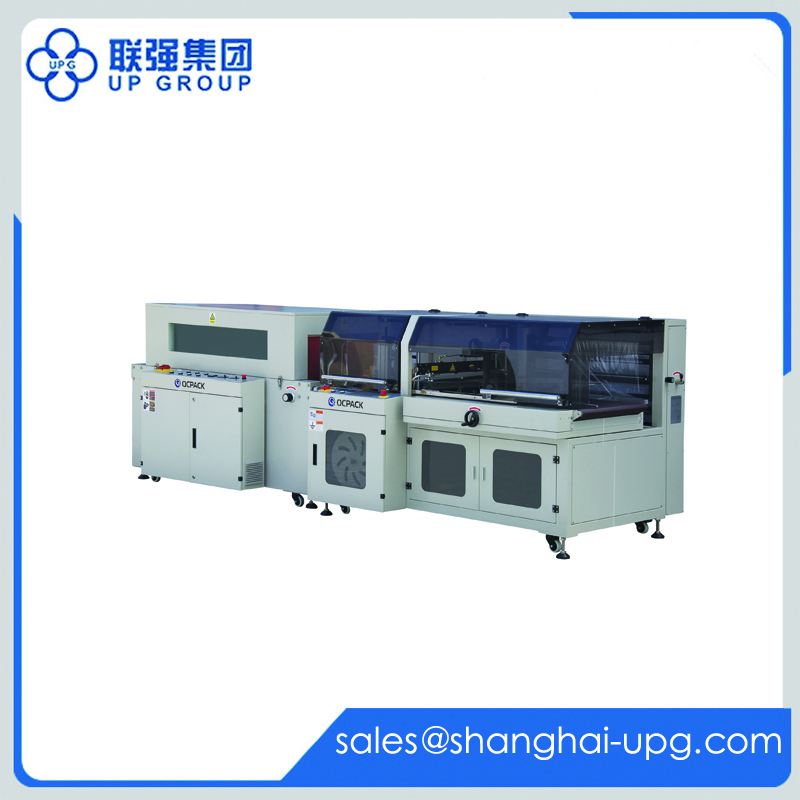

LQ-BM-500LX Automatic L Type Vertical Shrink Wrapping Machine

Automatic L type vertical shrink wrapping machine is a new type automatic shrink packingmachine. lt has a high degree of automation and can automatically complete the steps offeeding, coating, sealing and shrinkage. The cutting tool is driven by a four column verticalsystem, which can make the sealing line in the middle of the product.The sealing heightcan be adjusted to reduce the stroke time and improve the production speed.

-

LQ-BM-500L/LQ-BM-700L Constant Temperature Shrink Tunnel

The machine adopts roller conveyor, high temperature resistant silicone tube each drumoutsourcing can free rotation.Stainless steel heating tube, three layers of internal insulation,bi-directional thermal cycling wind heat evenly, constant temperature.Imported double frequencyconversion, can adjust the blowing and conveying speed to achieve the best effect.With threelayers of explosion-proof glass observation window to easy watch packing result of each product.

-

LQ-BM-500A Constant Temperature Shrink Tunnel

The machine adopts roller conveyor, high temperature resistant silicone tube each drumoutsourcing can free rotation.Stainless steel heating tube, internal three layer heat insulation, highpowercycle motor, bi-directional thermal cycling wind heatevenly,constant temperature.Temperature and conveying speed can be adjusted, ensure contract products to havebest packing effect. Hot air circulation channel,return type heat furnace tank structure, hot air onlyrun within the furnace chamber, prevent heat loss effectively.

-

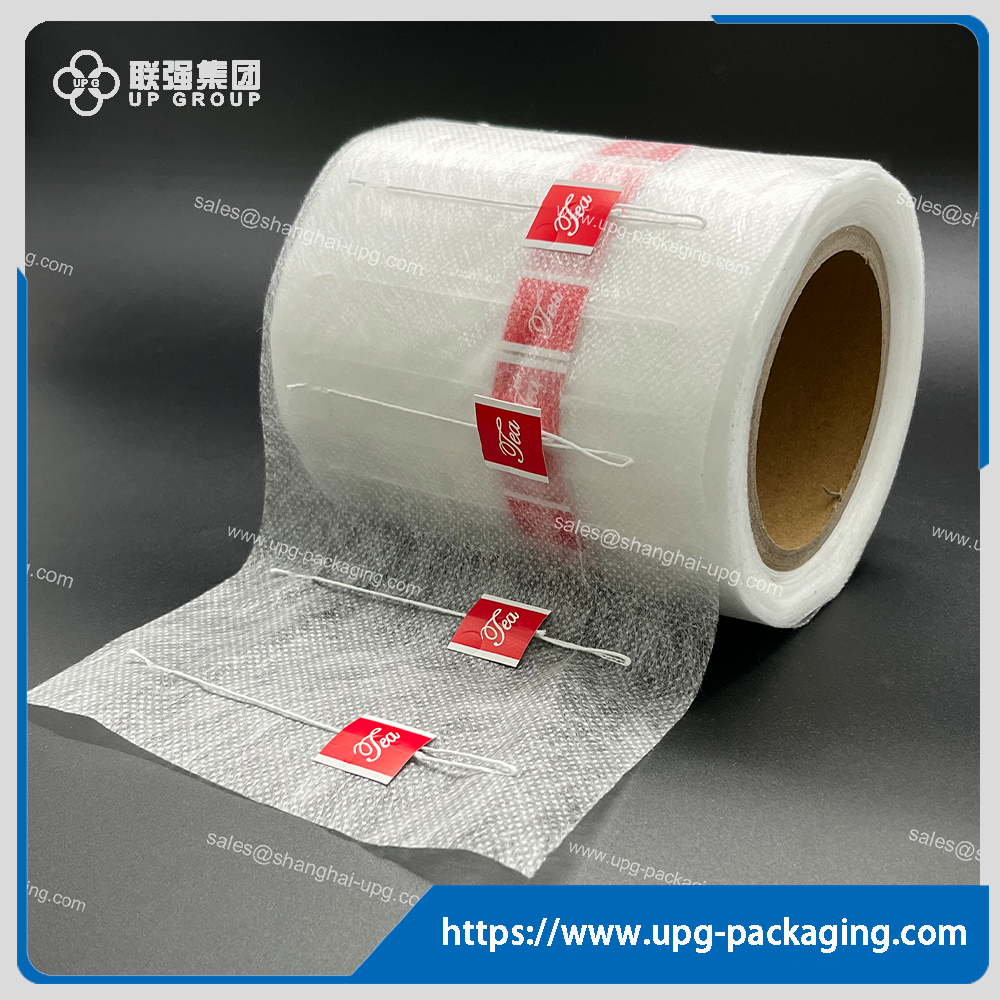

Nylon Filter for Tea Bag

Each carton has 6 rolls. Each roll is 6000pcs or 1000 meter.

The delivery is 5-10days.

-

PLA Soilon Filter for Pyramid Tea Bag with Tea Powder, Flower Tea

This product is used for packaging tea, flower tea and so on. The material is PLA mesh. We can provide filter film with label or without label and pre-made bag.

-

PLA non woven Filter for Tea Bag

This product is used for pacakging tea, flower tea, coffee and so on. The material is PLA non woven. We can prvoide filter film with label or without label and pre-made bag.Ultrasonic machines are suitable. -

.jpg)

LQ-DL-R Round Bottle Labeling Machine

This machine is used to label the adhesive label on the round bottle. This labeling machine is suitable for PET bottle, plastic bottle, glass bottle and metal bottle. It is a small machine with low price which can put on desk.

This product is suitable for round labeling or semi-circle labeling of round bottles in food, pharmaceutical, chemical, stationery, hardware and other industries.

The labeling machine is simple and easy to adjust. The product is standing on the conveyor belt. It achieves labeling accuracy of 1.0MM, reasonable design structure, simple and convenient operation.

-

LQ-BTH-550+LQ-BM-500L Automatic Side Sealing Shrink Wrapping Machine

This machine is suitable for packing long items (such as wood, aluminum, etc.). It adopts the most advanced Imported PLC programmable controller, with safety protection and alarm device, to ensure the machine high-speed stability. A variety of Settings can be easily completed on the touch screen operation. Use side sealing design, there is no limit of product packaging length. The sealing line height can be adjusted according to the packing product height. It is equipped with imported detection photoelectric, horizontal and vertical detection in one group, with easy to switch selection.

-

LQ-BTH-700+LQ-BM-700L Automatic High Speed Side Sealing Shrink Wrapping Machine

The machine is suitable for packing long items( such as wood, aluminum, etc.). Adopt the most advanced imported plc prohrammable controller, with safety protection and alarm device, ensure the machine high-speed stability, a variety of settings can be easily completed on the touch screen operation. Use side sealing design, no limited of product packaging length, the sealing line height can be adjusted according to the packing product height. Equipped with imported detection photoelectric, horizontal and vertical detection in one group, easy to switch selection.

Side blade sealing continuously makes the unlimited length of the product.

Side sealing lines can be adjusted to the desired position which based on the product’s height in order to achieve excellent sealing results.

-

LQ-XKS-2 Automatic Sleeve Shrink Wrapping Machine

Automatic sleeve sealing machine with shrink tunnel is suitable for shrink packaging of the beverage, beer, mineral water, pop-top cans and glass bottles etc without tray. Automatic sleeve sealing machine with shrink tunnel is designed for packing single product or combined products without tray. the equipment can be connected with the production line to complete feeding, film wrapping, sealing & cutting, shrinking and cooling automatically. There are various packing modes available. For combined object, the bottle quantity can be 6, 9, 12, 15, 18, 20 or 24 etc.

-

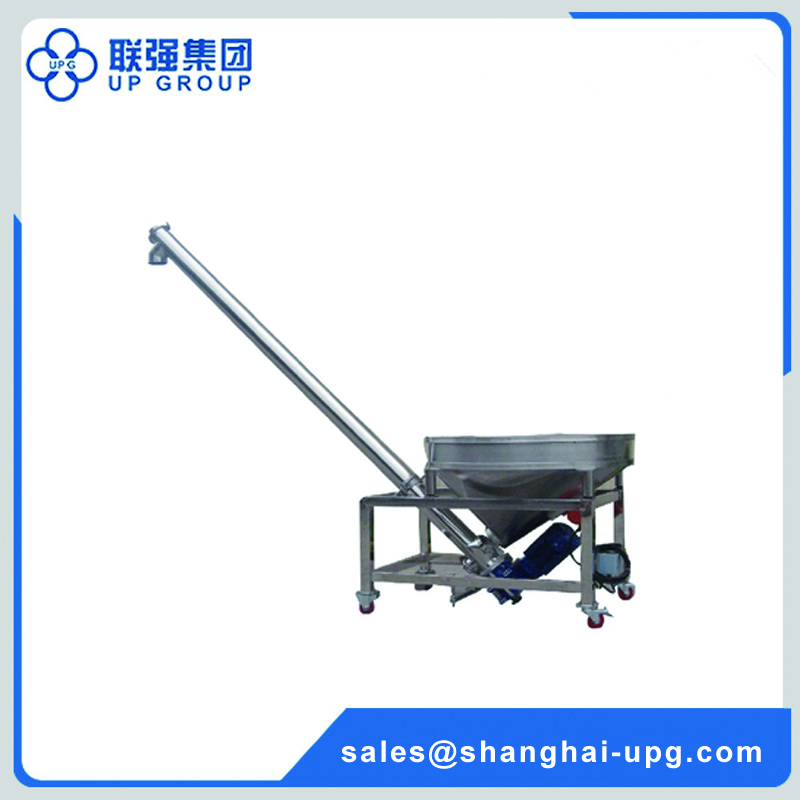

LQ-LS Series Screw Conveyor

This conveyor is suitable for multiple powder. Working together with packaging machine, the conveyor of the product feeding is controlled to retain the product level in the product cabinet of packaging machine. And the machine can be used independently. All parts are made of stainless steel except the motor, bearing and support frame.

When the screw is rotating, under the multiple force of pushing of blade, gravity force of material, friction force between material and tube inwall, inner friction force of the material. The material move forward inside the tube with the form of relative slide between the screw blades and tube.