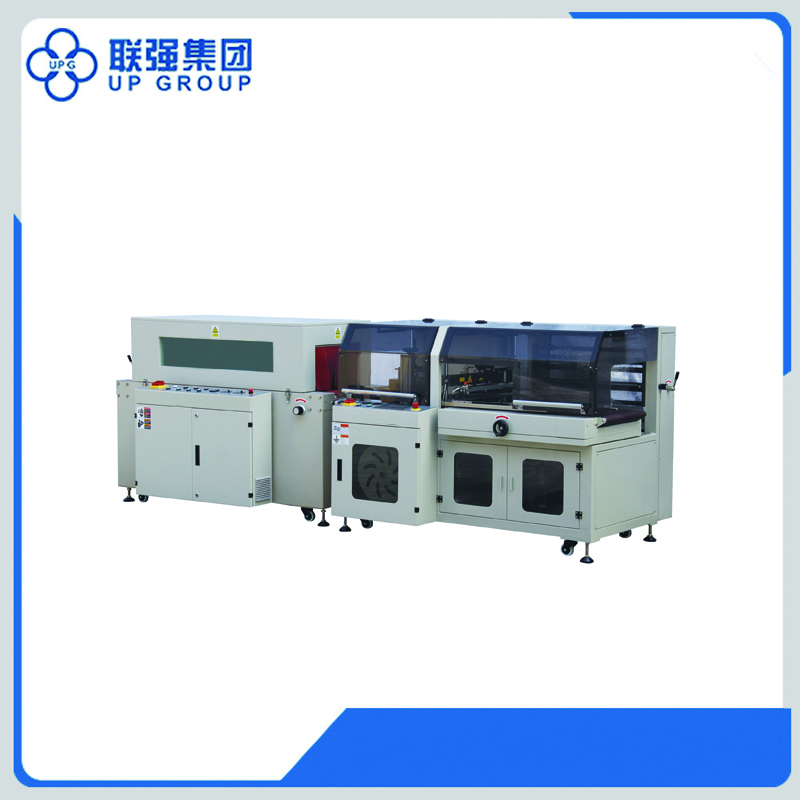

PriceList for Shrink Packaging Machine - LQ-BTH-700+LQ-BM-700L Automatic High Speed Side Sealing Shrink Wrapping Machine – UPG

PriceList for Shrink Packaging Machine - LQ-BTH-700+LQ-BM-700L Automatic High Speed Side Sealing Shrink Wrapping Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

The machine is suitable for packing long items( such as wood, aluminum, etc.). Adopt the most advanced imported plc prohrammable controller, with safety protection and alarm device, ensure the machine high-speed stability, a variety of settings can be easily completed on the touch screen operation. Use side sealing design, no limited of product packaging length, the sealing line height can be adjusted according to the packing product height. Equipped with imported detection photoelectric, horizontal and vertical detection in one group, easy to switch selection.

TECHNICAL PARAMETER

| Model | LQ-BTH-700 | LQ-BM-700L |

| Max. Packing Size | (L) No Limited (W+H)≤ 650mm(H)≤ 250mm | (L)No Limited*(W)680*(H)350mm |

| Max. Sealing Size | (L)No Limited (W+H)≤ 700mm | (L)2200*(W)700*(H)400mm |

| Packing Speed | 1-25 Packages/min | 0-30m/min |

| Electric Suppy&Power | 380V/50Hz 3kw | 380V/50Hz 16kw |

| Max. Current | 6A | 32A |

| Air Pressure | 5.5kg/cm3 | / |

| Weight | 760kg | 630kg |

| Overall Dimensions | (L)2250*(W)1420*(H)1300mm | (L)2504*(W)1300*(H)1400mm |

FEATURE

1. Side blade sealing continuously makes the unlimited length of the product;

2. Side sealing lines can be adjusted to the desired position which based on the product’s height in order to achieve excellent sealing results;

3. It adopts the most advanced OMRON PLC controller and touch operator interface. Touch operator interface accomplish all working date easily;

4. Sealing knife uses the aluminum knife with DuPont Teflon with anti-stick coating & anti-high temperature to avoid cracking, coking and smoking to achieve “zero pollution”。The machine itself is also equipped with automatic protection function which effectively prevent from accidental cutting; If you open the cover during the machine running, the machine will stop running and alarm.

5. Automatic film feeding punching deice is to drill away the air and make sure the packing result is good;

6. Equipped with imported USA Banner photoelectric of horizontal and vertical detection to easily finish the sealing of thin and small items;

7. Manually adjustable film-guide system and feeding conveyor platform make the machine suitable for different width and height items. When the packaging size changes, the adjustment is very simple by rotating the hand wheel without changing molds and bag makers;

8. LQ-BM-700L adopts advance circulation blowing from the bottom of the tunnel, equipped double frequency inverter controls blowing, adjustable blowing direction and volume form bottom.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment: 30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Delivery Time: 14 days after receiving deposit.

Warranty: 12 months after B/L date

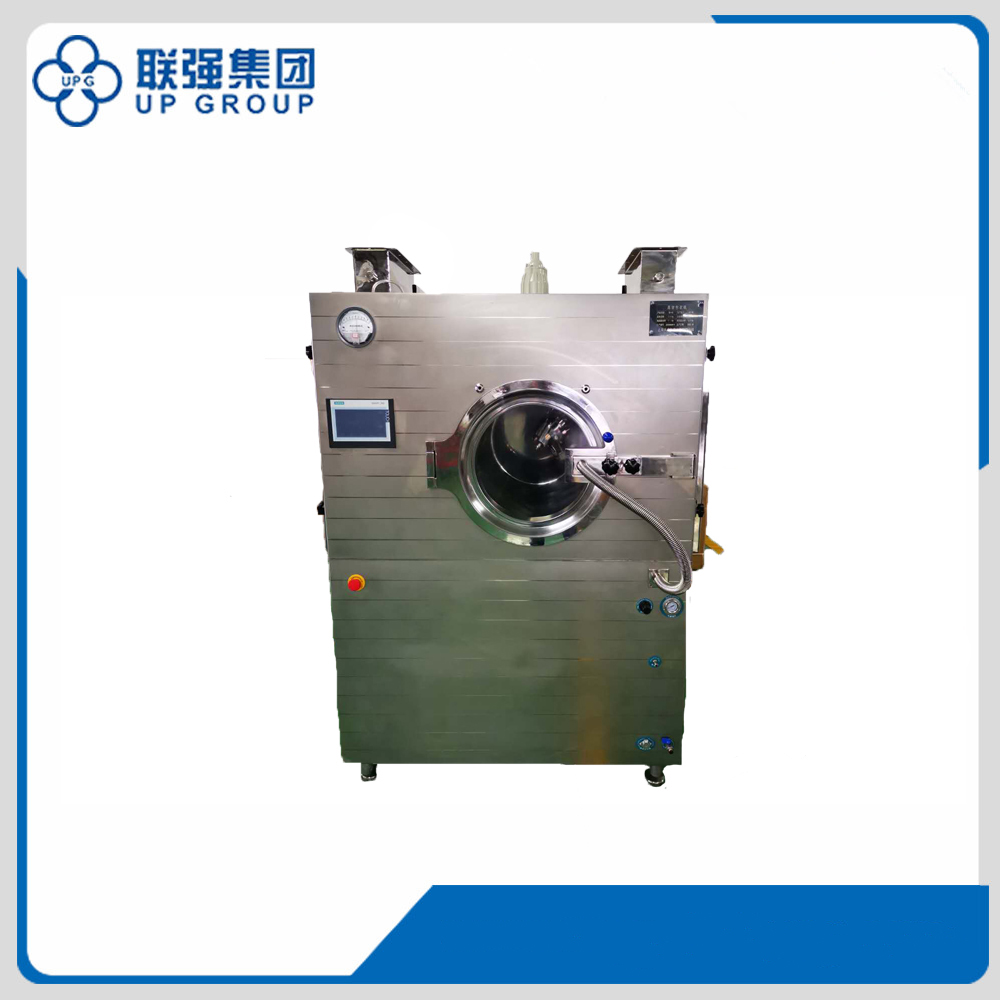

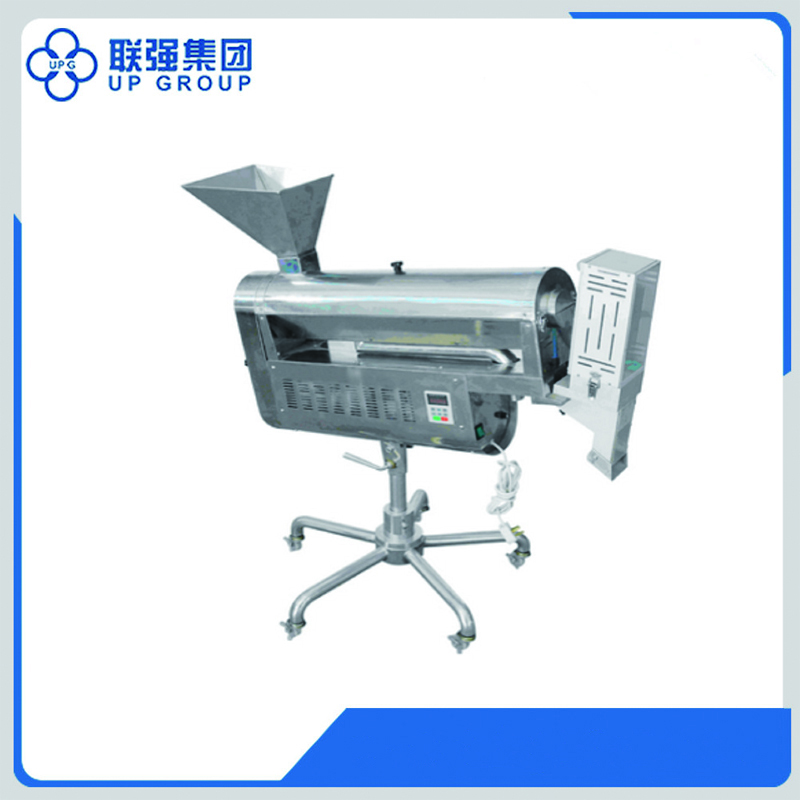

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for PriceList for Shrink Packaging Machine - LQ-BTH-700+LQ-BM-700L Automatic High Speed Side Sealing Shrink Wrapping Machine – UPG , The product will supply to all over the world, such as: Mombasa, Uruguay, Surabaya, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.