Professional Design Pill Deduster - LQ-RJN-50 Softgel Production Machine – UPG

Professional Design Pill Deduster - LQ-RJN-50 Softgel Production Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

This production line consists of main machine, conveyor, drier, electric control box, heat preservation gelatin tank and feeding device. The primary equipment is the main machine.

TECHNICAL PARAMETER

1. Main machine

| Speed | 5000-10000 capsules/hour (considering about 500mg soft capsule. The speed depends on the capsule size.) |

| Rotating speed of die roller | 0-5rpm (adjustment with frequency inverter) |

| Fill weight variation | ≤±1% (considering about oil product) |

| Feeding quantity of each piston of the feeding pump | 0~1.5mL(standard) |

| Roll size | Φ64×65mm |

| Machine power | 1.5kw |

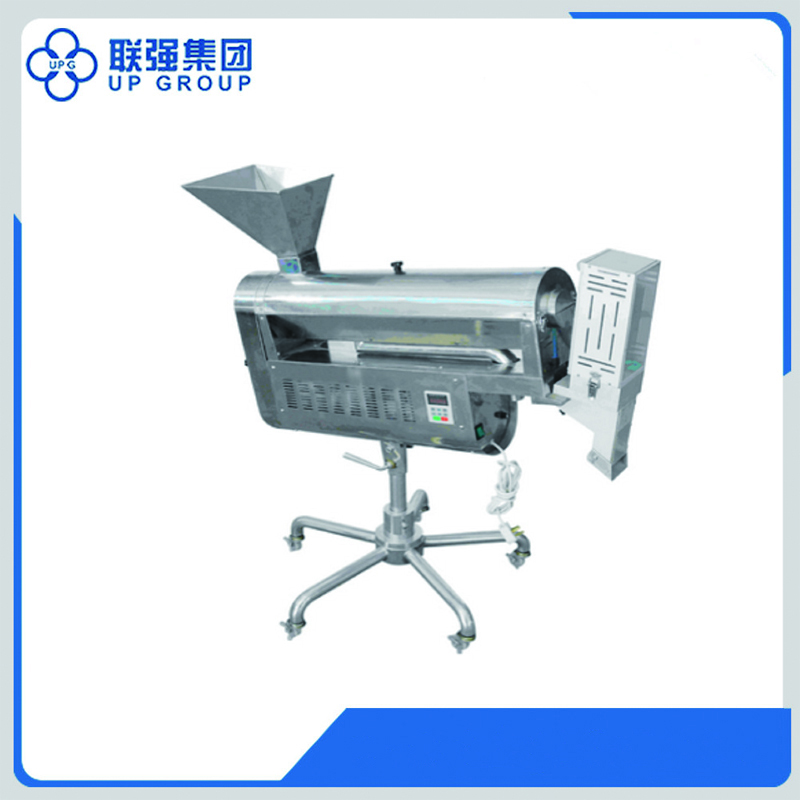

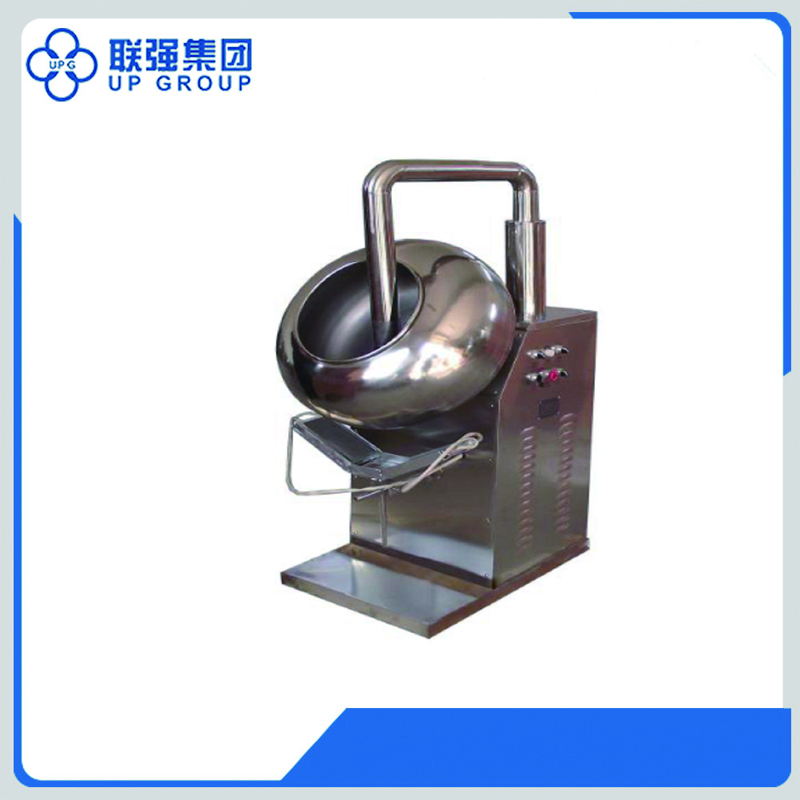

2. Drier

| Quantity of tumbler | 1 section |

| Tumbler size | φ320×450 mm |

| Tumbler rotating speed | 1.6 rpm |

| Machine power | 0.4kw |

| Fan motor power | 0.04 kW |

3. Pneumatic heat preservation tank

| Storage quantity | 30 L |

| Pressure in barrel | -0.09MPa ~ +0.06MPa |

| Electric heater power | 1.5kw |

| Stirring power | 0.1 kw |

4. Tray

| Trolley | 755mm×550mm×100mm |

| Tray size | 720mm×520mm×50mm |

| Quantity | 10pcs |

5. Working table

| Size | 1200mm*650mm*800mm |

4. Water chiller

| Cooling temperature | -5~16℃ |

| Coolant capacity | 35L |

| Power | 1kw |

FEATURE

1. Oil bath type electric heating spray body (patented technology) :

1) The spray temperature is uniform, the temperature is stable, and the temperature fluctuation is guaranteed to be less than or equal to 0.1℃. It will solved the problems like false joint, uneven capsule size which is caused by uneven heating temperature.

2) Due to the high temperature accuracy can reduce the film thickness about 0.1mm (save gelatin about 10%).

2. The computer adjusts the injection volume automatically. The advantage is save time, save raw materials. It is with high loading accuracy, loading accuracy is ≤±1%, greatly reduce the loss of raw materials.

3. Reversing plate, upper and lower body, left and right pad hardness to HRC60-65, so it is durable.

4. Mold lock plate is three-point lock, so mold locking operation is simple.

5. Minimal lubrication system reduces paraffin oil consumption and saves cost. And the oil quantity is automatically adjusted according to the speed.

6. The machine is installed with built-in cold air system, equipped with chiller.

7. Rubber roll adopts separate frequency conversion speed regulation. If the quality of rubber liquid is not good during production, it can be solved by adjusting the speed of rubber roll.

8. Cold air styling design in the pellet area so the capsule forming more beautiful.

9. Special wind bucket is used for the pellet part of the mold, which is very convenient for cleaning.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for Professional Design Pill Deduster - LQ-RJN-50 Softgel Production Machine – UPG , The product will supply to all over the world, such as: Indonesia, New Zealand, South Africa, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!