Super Purchasing for Bottle Capper - LQ-NJP Automatic Hard Capsule Filling Machine – UPG

Super Purchasing for Bottle Capper - LQ-NJP Automatic Hard Capsule Filling Machine – UPG Detail:

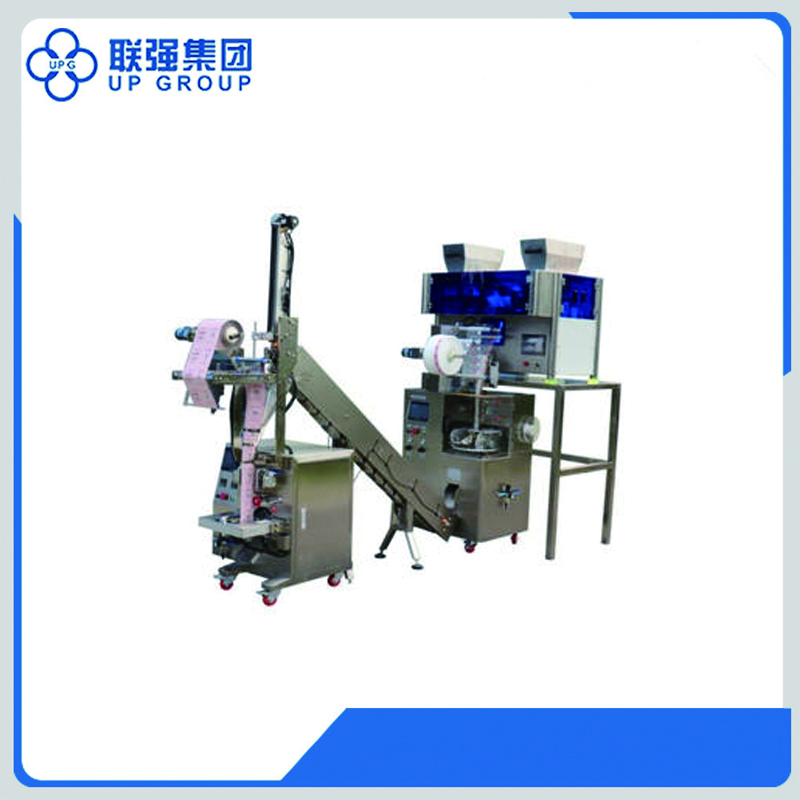

APPLY PHOTOS

INTRODUCTION

This machine applies the once transmission principle. It uses the slot wheel dividing system to drive the table to do intermittent movement. The machine has 8 sits. Expect manually putting the tubes on the machine, it can automatically fill the material into the tubes, heat both inside and outside of the tubes, seal the tubes, press the codes, and cut the tails and exit the finished tubes.

TECHNICAL PARAMETER

|

Model |

LQ-TFS-A |

LQ-TFS-B |

|

Tube Material |

Plastic Tube, Laminate Tube |

Metal Tube, ALU Tube |

|

Dia. of Tube |

19-50mm |

15-50mm |

|

Filling Volume |

2.5-250ml (customized) |

5-100ml (customized) |

|

Filling Accuracy |

±1% |

±1% |

|

Capacity |

1500-1800pcs/h |

1800-3600 pcs/h |

|

Air Consumption |

0.3m³/min |

0.2m³/min |

|

Power |

0.75kw |

1.5kw |

|

Voltage |

220V |

220V |

|

Overall Dimension(L*W*H) |

1100mm*800mm*1600mm |

1000mm*600mm*1700mm |

|

Weight |

250kg |

400kg |

FEATURE

1. Application: the product is suitable for automatic color coding, filling, tail sealing, printing and tail cutting of various plastic pipes and aluminum-plastic composite pipes. It is widely used in daily chemical, pharmaceutical, food and other industries.

2. Features: the machine adopts touch screen and PLC control, automatic positioning and hot air heating system formed by imported fast and efficient heater and high stability flow meter. It has firm sealing, fast speed, no damage to the appearance of the sealing part, and beautiful and neat tail sealing appearance. The machine can be equipped with various filling heads of different specifications to meet the filling requirements of different viscosities.

3. Performance:

a. The machine can complete bench marking, filling, tail sealing, tail cutting and automatic ejection.

b. The whole machine adopts mechanical cam transmission, strict precision control and processing technology of transmission parts, with high mechanical stability.

c. High precision processing piston filling is adopted to ensure the filling accuracy. The structure of quick disassembly and quick loading makes the cleaning easier and more thorough.

d. If the pipe diameters are different, the replacement of the mold is simple and convenient, and the replacement operation between large and small pipe diameters is simple and clear.

e. Stepless variable frequency speed regulation.

f. Precise control function of no tube and no filling – controlled by precise photoelectric system, the filling action can be started only when there is a hose on the station.

g. Automatic exit hose device – finished products that have been filled and sealed automatically exit from the machine to facilitate connection with cartoning machine and other equipment.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping.Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Super Purchasing for Bottle Capper - LQ-NJP Automatic Hard Capsule Filling Machine – UPG , The product will supply to all over the world, such as: Russia, Ottawa, Bangladesh, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!