Tea Bag Packaging Machine

Introduction:

This machine is used to package tea as flat bag or pyramid bag. It packages different tea in one bag. (Max. tea kind is 6 kinds.)

Features:

The main feature of the machine is that the inner and outer bags are formed at one time, avoiding direct contact between hands and materials, and improving efficiency. The inner bag is made of nylon mesh, non-woven fabric, corn fiber, etc., which can be automatically attached with thread and label, and the outer bag is made of composite materials. Its biggest advantage is that the packaging capacity, inner bag, outer bag, label, etc. can be adjusted at will, and the size of inner and outer bags can be adjusted according to the different needs of users, so as to achieve the best packaging effect, improve the product appearance and enhance the product value.

1. It is used for plane packaging, triangle three-dimensional packaging and other products. It can easily switch between two packaging forms, namely, plane packaging and triangle three-dimensional packaging, with a single button.

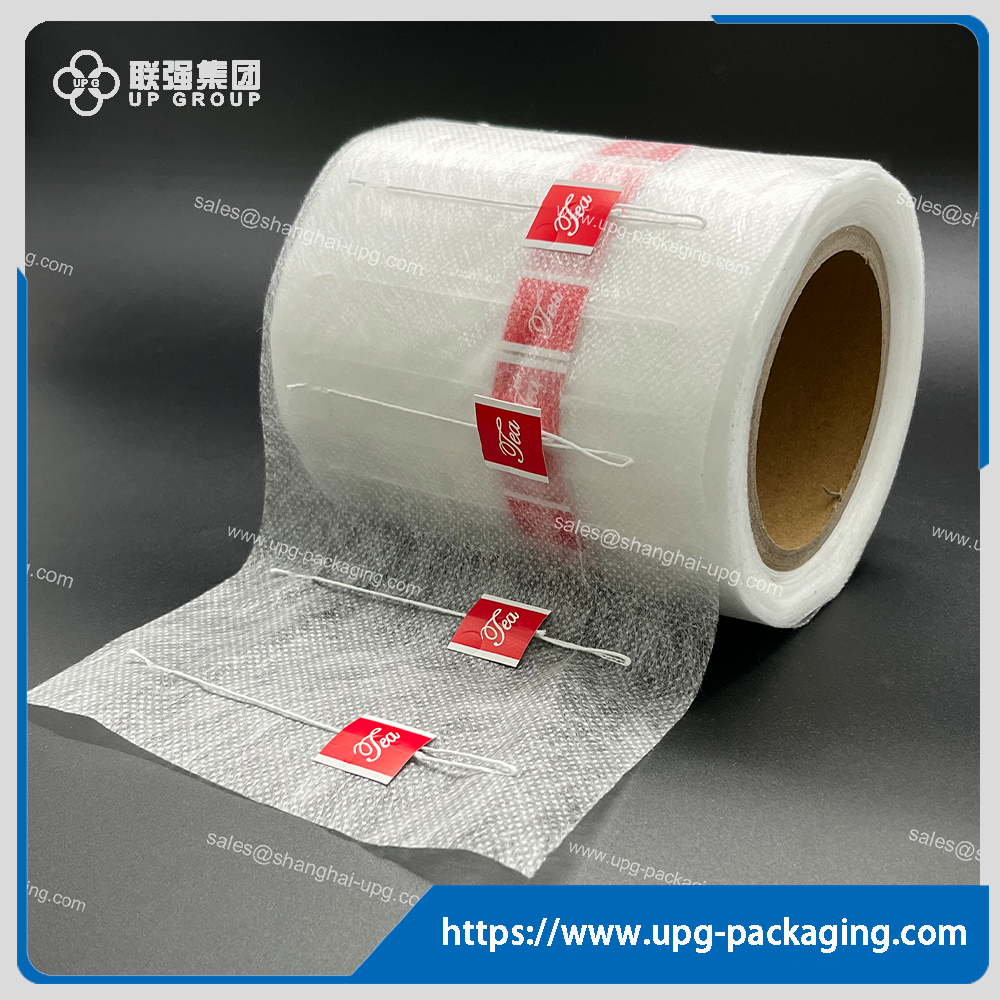

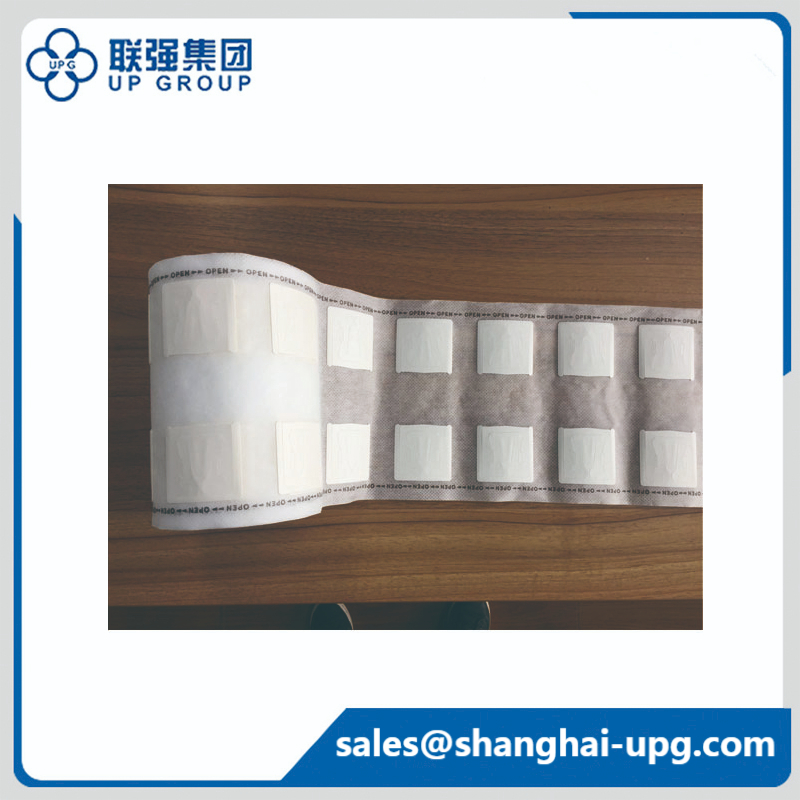

2. The machine can use packaging roll film with wire and label.

3. According to the material characteristics, the electronic weighing and blanking system can be configured. The electronic weighing and blanking system is suitable for single material, multi material, irregular shaped materials, and other materials that cannot be weighed by ordinary measuring cups. The electronic weighing and blanking system can independently and flexibly control the measuring weight of each scale according to the requirements.

4. Precise electronic scale can greatly improve the production efficiency of the equipment due to its accurate blanking method.

5. Touch human-machine panel, Mitsubishi PLC controller, using servo motor to make bags, provide complete setting function, can adjust multiple parameters according to needs, and provide users with maximum operating flexibility.

6. Main motor protection device (cycle timeout).

7. It has the packaging film tension compensation function, which can eliminate the influence of the change of packaging film tension on the packaging bag length.

8. Automatic fault alarm and automatic shutdown.

9. The whole machine can automatically complete the functions of blanking, metering, bag making, sealing, cutting, counting, finished product conveying, etc.

10. The precise control system is used to adjust the action of the whole machine, with compact structure, man-machine interface design, convenient operation, adjustment and maintenance. The bag length is driven by a stepping motor, with stable bag length, accurate positioning and convenient debugging.

11. Pneumatic control technology is adopted in many places, with simple and compact structure.

12. The inner bag adopts ultrasonic sealing and cutting technology, and the sealing is firm and reliable.

13. The inner and outer bags can be switched independently, which can be linked or operated separately.

14. Photoelectric automatic tracking of color dots, accurate trademark positioning.

Technical specification:

|

Machine Name |

Tea Bag Packaging Machine |

|

Weighting method |

4-head or 6-head weigher |

|

Working speed |

About 30-45 bags/min (depend on tea) |

|

Filling accuracy |

±0.2 grams/bag (Depend on the tea) |

|

Weight range |

1-20g |

|

Inner bag material |

Nylon, PET, PLA, non-woven fabrics and other ultrasonic materials |

|

Outer bag material |

Composite film, pure aluminum film, paper aluminum film, PE film and other heat sealable materials |

|

Inner bag film width |

120mm / 140mm / 160mm |

|

Outer bag film width |

140mm / 160mm / 180mm |

|

Inner bag sealing method |

Ultrasonic |

|

Outer bag sealing method |

Heat sealing |

|

Inner bag cutting method |

Ultrasonic |

|

Outer bag cutting method |

Cutting knife |

|

Air pressure |

≥0.6Mpa |

|

Power supply |

220V, 50Hz, 1Ph, 3.5KW (Power supply can be customized) |

|

Machine size |

3155mm*1260mm*2234mm |

|

Machine weight |

About 850kg |

Configuration:

|

Name |

Brand |

|

PLC |

Mitsubishi (Japan) |

|

Touch Screen |

Weinview (Taiwan) |

|

Servo motor |

Shihlin (Taiwan) |

|

Servo driver |

Shihlin (Taiwan) |

|

Magnetic Valve |

AirTac (Taiwan) |

|

Photo-electric Sensor |

AUFONICS (China) |